You can join strip edges in three ways: butt seam, overlap seam, or double-cut seams.

► The butt seam is the most common, its edges are simply butted together and rolled with a seam roller.

► An overlap seam is better where corners are out of sguare or when a butt seam might occur in a corner and not cover well. Keep the overlap as narrow as possible, thereby avoiding a noticeable welt and patterns that are grossly mismatched.

► Double-cut seams (also called through-cut seams) are the most complex of the three. They are used primarily where patterns are tough to match or surfaces are irregular; for example, where the walls of an alcove aren’t sguare.

How to Cut Seams________________________

|

OVERLAP SEAM DOUBLE-CUT SEAM

|

covering are called straight match. Patterns that run diagonally are called drop match and waste somewhat more material during alignment.

covering are called straight match. Patterns that run diagonally are called drop match and waste somewhat more material during alignment.

Unless you are working with a delicate covering, cut several strips at a time. But be careful not to crease them. Flop the entire pile of strips face down on the table so the piece cut first will be the first pasted and hung. The table must be perfectly clean; otherwise, the face of the bottom strip could become soiled.

PASTING

Unless you’re experienced, buy a premixed adhesive. But if mix you must, try to achieve a mixture that’s slightly tacky to the touch. Add paste powder or water slowly: Even small increments can change the consistency radically. Finally, mix thoroughly to remove lumps.

As you work, keep the pasting table clean, quickly sponging up stray paste so it won’t get on strip faces. Some coverings, such as vinyl, are not marred by stray paste on their face, but many others could be. Although the batch of paste you mix should last a working day, keep an eye on its consistency. Paste should glide on, never drag. Rinse the paste brush or roller when you break for lunch and when you quit for the day.

Until you become familiar with papering, apply paste to only one strip at a time. Using a roller, apply paste in the middle of the strip, toward the top. Spread the paste to the far edge and then to the near edge. For good measure, run the roller over strip edges twice because it’s often hard to see if the paste along the edges is evenly spread.

Prepasted Papers and Water Trays

Most wallcoverings come prepasted. Typically, manufacturers specify that individual strips be soaked for 30 seconds in a water tray filled with lukewarm water. But follow the directions printed on the back or supplied by the retailer. After soaking, pull each strip out of the tray and onto the work table, book (fold) it, and allow it to expand before hanging it on the wall. Precut the pieces before placing them in the water tray. Otherwise, if you try to trim soaked strips, they’ll snag or tear.

Many professional paperhangers will hang prepasted wallcoverings but hate water trays because (1) water and diluted paste drips everywhere; (2) the water in the tray must be changed often; (3) a thin film of paste also ends up on the front of the wallcovering; and (4) if the strips are soaked too long, they may not adhere well.

Instead, these pros roll prepaste activator onto the backing of strips, just as you’d apply standard paste. Rolling on an activator reduces mess and ensures good adherence to the wall.

Last, pros sometimes roll thinned-down paste instead of activator. That may be okay, but first ask the wallcovering supplier if the two pastes will be compatible.

Last, pros sometimes roll thinned-down paste instead of activator. That may be okay, but first ask the wallcovering supplier if the two pastes will be compatible.

Position the upper end of the strip an inch or so above the ceiling line. Smooth the upper end of the strip first, by running a smoothing brush down the middle of the strip and out toward the edges. Working from the center outward, brush air bubbles, wrinkles, and excess paste from the middle to the edges. Align subsequent pieces to the leading edge of each preceding strip, checking periodically to make sure the strips are plumb.

If the upper half of the strip is adhering well, simply unfold the lower fold and smooth the paper down, again brushing down the center and out toward the edges with small strokes.

If a butt seam doesn’t meet exactly, you have three choices:

Move a strip slightly by raising one of its edges, and—palm on paper—using your other hand to slide the strip toward or away from the seam. Raising one edge of the strip reduces the grip between paper and wall.

Pull the strip off the wall, realign its patterns along the seam, and brush it down.

But you’ve got to move quickly: Don’t wait much more than a minute to pull the strip off.

Pull off the strip, quickly sponge clean the wall, and hang a new strip.

Don’t try pulling just one edge of the strip, however. At best, it will stretch, draw back when it dries, and open the seam. At worst, you’ll pucker or rip the strip.

SPONGING

It’s impossible to overstate the importance of gently wiping paste off the wallcovering and adjacent surfaces. Left on the wallcovering, paste can shrink and pull the ink off. If paste dries on a painted ceiling, it will pull the paint off. (If you see a brown crust along a ceiling-wall intersec-

Dry-HANGING

If handled too much, many fabrics, foils,

Mylars, and grasses will separate from their backing once they absorb the paste. For that reason, pros often dry-hang them. Here’s how: They roll paste onto the wall and smooth the dry covering onto it. However, leave this job to a pro because the paste must be applied impeccably even, and the strips placed exactly— there’s little chance to adjust them. Likewise, these materials can’t tolerate sponging, rubbing, or seam rolling. Pros sweep them on with a soft-bristle smoothing brush and let them be.

tion, that’s dried paste.) Paste will even pull the finish off wood trim. Vinyl-on-vinyl and clay adhesives are especially tenacious, so sponge off the excess immediately.

Equally important: Change your sponge water often so diluted paste doesn’t accumulate. Warm water is best. And wring the sponge almost dry before wiping. When you’ve wiped the surfaces

clean, come back with a soft, dry rag. But apply only light pressure so you don’t move the wallcovering, disturbing its seams.

Note: Don’t rub delicate wallpapers. Instead, blot them clean with a just-damp sponge. Before you commit to any wallcovering, ask your supplier if it can be wiped (or blotted clean) with a sponge. If not, consider other materials.

TRIMMING AND ROLLING

Where a strip of wallcovering meets borders such as woodwork, a ceiling line, or a baseboard, use a 6-in. taping knife to press the edges of the covering snug. Cut off the excess by running a razor knife along the blade of the taping knife. Because strips may cover door or window casing, you may want to rough-cut the ends of strips first so you don’t cut them too short. Then, using your taping knife to tuck the wallcovering snugly against the casing, trim it more precisely. For clean cuts, razor blades must be sharp.

Conventional wisdom suggests rolling wallcovering seams 10 minutes or 15 minutes after the strips are in place—that is, after the paste has set somewhat. But the master craftsman shown hanging wallpaper in photos here prefers to the roll seams before he brushes out the paper. If you position the strips correctly, roll the seams, and then smooth the covering, he asserts, you’re less likely to stretch the wallpaper. Also, if seams don’t align correctly, you want to know that sooner, rather than later, so you can adjust or remove the strip before the paste sets up.

In any case, rolling may cause paste to ooze from the seams. So, be sure to sponge wallcovering clean as you work, unless you’re installing delicate or embossed wallcovering, which shouldn’t be rolled or wiped at all. Finally, use a moderate pressure when rolling. After all, you’re trying to embed the wallcovering in the paste, not crush it.

Outside comers. Outside comers project into a room and so are very visible. So when laying out the job, never align the edge of a strip to the edge of an outside comer. Such edges look terrible initially and then usually fray. If the edge of a strip would occur precisely at a corner, cut it back h in. and wrap the corner with the edge of a full strip from the adjacent wall. Relief cut the top of the wallcovering where it turns the corner, as shown in the photo below, so the top of strip can lie flat. Remember to plumb the leading edge of the new strip.

Outside comers. Outside comers project into a room and so are very visible. So when laying out the job, never align the edge of a strip to the edge of an outside comer. Such edges look terrible initially and then usually fray. If the edge of a strip would occur precisely at a corner, cut it back h in. and wrap the corner with the edge of a full strip from the adjacent wall. Relief cut the top of the wallcovering where it turns the corner, as shown in the photo below, so the top of strip can lie flat. Remember to plumb the leading edge of the new strip.

covering are called straight match. Patterns that run diagonally are called drop match and waste somewhat more material during alignment.

covering are called straight match. Patterns that run diagonally are called drop match and waste somewhat more material during alignment.

Last, pros sometimes roll thinned-down paste instead of activator. That may be okay, but first ask the wallcovering supplier if the two pastes will be compatible.

Last, pros sometimes roll thinned-down paste instead of activator. That may be okay, but first ask the wallcovering supplier if the two pastes will be compatible.

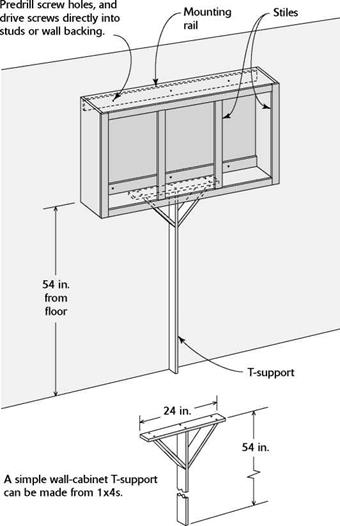

an electrical line coming in, if a garbage disposal unit and/or a dishwasher will be installed (see the bottom photo on p. 254). Measure from the floor and the adjoining cabinet to locate the centers of the access holes. You can use a jigsaw or a drill with a hole saw to cut the holes. Drill slowly and leave a neat-looking job. Seal any holes around pipes with expanding foam or caulk. FILL GAPS WITH STRIPS. At times you may need a vertical filler strip to close a gap between the edge of a cabinet and an adjoining wall. A filler strip is like a stile. It is cut to the width of the gap and then screwed to the cabinet stile, as shown in the illustration

an electrical line coming in, if a garbage disposal unit and/or a dishwasher will be installed (see the bottom photo on p. 254). Measure from the floor and the adjoining cabinet to locate the centers of the access holes. You can use a jigsaw or a drill with a hole saw to cut the holes. Drill slowly and leave a neat-looking job. Seal any holes around pipes with expanding foam or caulk. FILL GAPS WITH STRIPS. At times you may need a vertical filler strip to close a gap between the edge of a cabinet and an adjoining wall. A filler strip is like a stile. It is cut to the width of the gap and then screwed to the cabinet stile, as shown in the illustration