CONSTRUCTION

The following material is presented in the format of a typical specification used by one agency for the construction of noise barriers (noise walls). In addition to the type of wall included—timber wall with concrete posts—it can be adapted to walls of other types.

A. Miscellaneous Structure Removal

Abandoned structures and other obstructions shall be removed from the right-of-way and disposed of in accordance with DOT provisions except as modified below:

All debris resulting from the removal items and all other materials that become the property of the contractor and are not recycled into the project shall be disposed of outside the right-of-way in accordance with DOT provisions. This work shall be incidental to removal and salvage operations, and no direct compensation will be made therefor.

The contractor’s attention is directed to possible privately owned appurtenances adjacent to the construction site that may need to be removed. If the private appurtenances are damaged, the contractor will be required to reinstate the appurtenances to satisfaction of owner. This work shall be considered incidental to the removal operations, and no direct compensation will be made therefor.

B. Clearing and Grubbing at Construction Site

The engineer shall have authority to limit the surface area of erodible earth material exposed by clearing and grubbing, excavation, and borrow and fill operations and to direct the contractor to provide immediate permanent or temporary control measures to prevent contamination of adjacent streams and other watercourses, lakes, ponds, and areas of water impoundment. Cut slopes shall be seeded and mulched as the excavation proceeds to the extent considered desirable and practicable.

The contractor will be required to incorporate all permanent erosion control features into the project at the earliest practicable time as outlined in his/her accepted schedules. Temporary pollution control measures will be used when needed to correct conditions that develop during construction but were not foreseen during the design stage, when needed prior to installation of permanent erosion control features, or when needed temporarily to control erosion that develops during normal construction practices; by definition, such temporary measures are not associated with the permanent control features on the project.

Where erosion is likely to be a problem, clearing and grubbing operations should be so scheduled and performed that grading operations and permanent erosion control features can follow immediately thereafter if the project conditions permit; otherwise, temporary erosion control measures may be required between successive construction stages. Under no conditions shall the surface area of erodible earth material exposed at one time by clearing and grubbing exceed 750,000 ft[21] (70,000 m2) without approval of the engineer.

C. Furnishing Concrete Post and Wood Noise Wall

This work shall consist of furnishing all materials for and constructing wood noise attenuator walls complete with concrete posts, and wood retaining wall, all in accordance with the plan details, the applicable DOT Standard Specifications, the required specifications for pigmented sealer and exterior wood surface stain, and the following:

1. General. All thickness and width dimensions of solid sawn wood for timber facing material indicated in the plans for wood wall construction shall be construed to be nominal dimensions unless otherwise indicated in the plans or these special provisions.

All lumber shall be pressure-treated with a preservative in accordance with the provisions of AASHTO M133 and the American Wood Protection Association (AWPA)

manual.

1. All wall facings and battens shall be treated with a pressure preservative as approved by AWPA.

2. Wood materials shall be treated as required for aboveground installation, or for installation in contact with ground or water, in accordance with the applicable provisions of AASHTO M133 with a retention level of 0.60 lb/ft3 (9.6 kg/m3).

3. All southern pine materials shall be free of sap stain (blue stain).

4. All wood members shall be kiln-dried to a moisture content of 15 percent or less after preservative treatment.

5. After completion of the preservative treatment, all lumber materials shall be protected from any increase in moisture content by covering or any other approved method until incorporated into the wall.

6. The same preservative treatment shall be used to treat bolt holes, saw cuts, etc., if any, and for any additional dressing deemed necessary by the engineer.

7. All treated wood members shall be cared for in accordance with the applicable provisions of AWPA Standard for the Care of Preservative Treated Wood Products.

1. Construction of wood noise attenuator walls, together with appurtenant posts, etc., shall be accomplished in accordance with the plan details, the applicable DOT Standard Specifications, these special provisions, or as otherwise approved by the engineer.

2. Nailing and fastening shall be accomplished in a manner that will avoid splitting boards. A 4-mil (0.10-mm) polyethylene sheeting may be placed between the planks and the earth for added protection when fill is being retained.

3. Joints shall be constructed in a manner that will completely arrest the passage of light. No daylight shall be visible through the joints 120 days after completion of the wall. The contractor is advised to take whatever measures are necessary to avoid excessive shrinkage or shifting that would cause the passage of light. Where passage of light does occur, the contractor shall take corrective action, in the form of caulking, or other means to the satisfaction of the engineer, at his/her own expense.

4. Storage of materials within the right-of-way will be permitted only as approved by the engineer.

5. Debris shall be disposed of outside the right-of-way as specified by the engineer. Posts shall be plumb after installation.

6. The trench and trench backfill shall be compacted by the ordinary compaction method. The trench bottom shall be compacted to 90 percent of maximum density, and the bedding to 95 percent and 90 percent on each side of the footing. The density control shall not apply to the topsoil. The layers of material to be compacted shall be placed and compacted simultaneously so that the backfill material will be raised uniformly throughout the entire embedment depth.

F. Noise Wall Measurement and Payment

1. Concrete posts of each size will be measured separately by the length of the posts furnished and installed complete in place as specified. Payment will be made at the contract bid price per linear foot, which shall be compensation in full for all costs relative thereto.

2. Noise wall construction will be measured by the total front face area of the wall constructed (i. e., the area between the centers of end posts, and between the top of the wall and 6 in (150 mm) below the tabulated ground line).

3. Payment will be made for noise attenuator wall at the contract bid price per square foot, which price shall be compensation in full for all costs of constructing the wall complete in place as specified, except the appurtenant concrete posts, which shall be compensated for separately under the appropriate contract item provided.

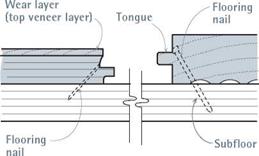

4. Instead of the hand-driven “full-head” nail as shown in the plan, a reduced-head power-driven nail may be used to meet one of the following modifications:

a. Use a nail one gauge heavier.

b. Increase the number of nails used in each pattern by a minimum of 50 percent.

For example, use 3 nails instead of 2, 5 instead of 3, 2 instead of 1.

5. In case of failure on the part of the contractor to control erosion, pollution, and sil – tation as ordered, the DOT reserves the right to employ outside assistance or to use its own forces to provide the necessary corrective measures. All expenses so incurred by the department, including its engineering costs, that are chargeable to the contractor as his/her obligation and expense, will be deducted from any monies due or coming due the contractor.

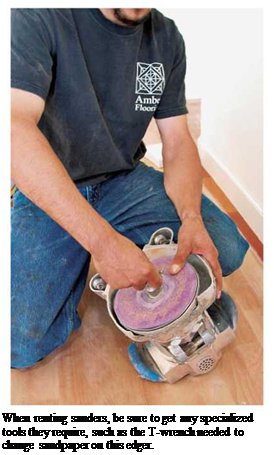

An edger (disk sander) goes where drum or belt sanders can’t—along the perimeter of floors and into tight nooks. (Large floor sanders should not be used within 6 in. of walls.) Edgers may be smaller than floor sanders, but they can still gouge flooring quickly. So first practice on plywood. The edger’s paper is held in place against a rubber disk by a washered nut. To prevent gouging the floor with the edger, many professionals leave three or four used disks beneath the new one, which cushions the cutting edge of the sandpaper somewhat.

An edger (disk sander) goes where drum or belt sanders can’t—along the perimeter of floors and into tight nooks. (Large floor sanders should not be used within 6 in. of walls.) Edgers may be smaller than floor sanders, but they can still gouge flooring quickly. So first practice on plywood. The edger’s paper is held in place against a rubber disk by a washered nut. To prevent gouging the floor with the edger, many professionals leave three or four used disks beneath the new one, which cushions the cutting edge of the sandpaper somewhat.