The FHWA has developed the following federal-aid policy guide that provides much useful information for the application of VE:

1. PURPOSE. To provide policy guidance on the application of value engineering in

the federal-aid highway program.

2. AUTHORITY.

a. Section 106(e) of Title 23, United States Code provides: “For such projects as the Secretary determines advisable, plans, specifications, and estimates for proposed projects on any Federal-aid system shall be accompanied by a value engineering or other cost reduction analysis.”

b. Section 106(g) of Title 23, United States Code provides: “The Secretary shall establish a program to require States to carry out a value engineering analysis for all projects on the National Highway System [NHS] with an estimated total cost of $25,000,000 or more.” The Federal Highway Administration published its regulation establishing this program on February 14, 1997.

c. Paragraph 6b(2) of DOT Order 1395.1A, Use of Value Engineering in the Department of Transportation, dated May 8, 1992, provides: “Each DOT Operating Administration should strongly encourage the use of VE in its grant awards or Federally assisted programs for major transportation projects throughout the planning, design and/or construction phases. This may include the use of VE proposals as a result of VE studies/analyses as well as VE incentive clauses in construction contracts.”

d. Paragraph 9 of the Office of Management and Budget’s (OMB) Value Engineering Circular A-131, dated May 21, 1993, provides: “Each agency shall report Fiscal Year results of using VE annually to OMB, except those agencies whose total budget is under $10 million or whose total procurement obligations do not exceed $10 million in a given fiscal year.” The Circular also describes what VE data must be submitted and the format for submitting the data to OMB.

3. DEFINITIONS.

a. Life cycle cost: The total cost of an item’s ownership over its life cycle. This includes initial acquisition costs (right-of-way, planning, design, construction), operation, maintenance, modification, replacement, demolition, financing, taxes, disposal, and salvage value as applicable.

b. Project: A portion of a highway that a state proposes to construct, reconstruct, or improve as described in the preliminary design report or applicable environmental document. A project may consist of several contracts or phases over several years.

c. Product or service: Any element of a highway project from concept through maintenance and operation. In all instances, the required function should be achieved at the lowest life cycle cost consistent with requirements for performance, maintainability, safety, and aesthetics.

d. Value engineering: The systematic application of recognized techniques by a multidisciplinary team to identify the function of a project or service, establish a worth for that function, generate alternatives through the use of creative thinking, and provide the needed functions to accomplish the original purpose of the project, reliably, and at the lowest life cycle cost without sacrificing safety, necessary quality, and environmental attributes of the project.

e. Value Engineering Change Proposal (VECP) clause: A construction contract provision that encourages the contractor to propose changes in the contract requirements which will accomplish the project’s functional requirements at less cost or improve value or service at no increase or a minor increase in cost. The net savings of each proposal is usually shared with the contractor at a stated reasonable rate.

4. POLICY. The FHWA will ensure that a VE study is performed on all federal-aid – funded NHS projects with an estimated cost (includes design, right-of-way, and construction costs) of $25 million or more, and on other federal-aid projects where its employment has high potential for cost savings. In addition, FHWA will strongly encourage state departments of transportation to use VE throughout highway project development, design, and construction.

5. CHARACTERISTICS. To be considered VE, the analysis process should incorporate each of the following characteristics:

a. A multidisciplinary team approach

b. The systematic application of a recognized technique (VE job plan)

c. The identification and evaluation of function, cost, and worth

d. The use of creativity to speculate on alternatives that can provide the required functions (search for solutions from new and unusual sources)

e. The evaluation of the best and lowest life cycle cost alternatives

f. The development of acceptable alternatives into fully supported recommendations

g. The presentation/formal reporting of all VE recommendations to management for review, approval, and implementation.

6. APPLICATION.

a. A VE analysis shall be applied to all federal-aid-funded NHS projects with estimated costs of $25 million or more; however, VE should not be limited to only projects of this scope. It can also be highly effective when used on other projects when there is potential for a significant ratio of savings to the cost of the VE study or substantial improvements in project or program effectiveness.

b. For maximum benefit, VE should be employed as early as possible in the project development/design process so valid VE recommendations can be implemented without delaying the progress of the project or causing significant rework of completed designs. States should schedule VE routinely into the project development/design process. While all projects will not necessarily benefit from the application of VE, the review process should be set up to consider all projects and a VE analysis should be applied to those projects offering the greatest potential for improvement and/or savings.

c. Recommendations from VE studies and VECPs should receive prompt reviews by state officials to determine their acceptability. States should also develop procedures for implementing accepted recommendations.

7. BACKGROUND INFORMATION. The FHWA’s text “Value Engineering for Highways” provides further details on the VE technique and its applicability to highway projects and functions. It has been widely distributed as a part of FHWA’s training effort and a copy should be available in each state DOT and FHWA office. Additional copies may be obtained from the FHWA VE coordinator. The American Association of State Highway and Transportation Officials (AASHTO) Guidelines for Value Engineering (AASHTO, Washington, D. C., 2001) also provides an excellent description of VE.

8. FHWA RESPONSIBILITIES.

a. Division office

(1) Designate a VE coordinator and encourage state to host VE training provided by the FHWA, a qualified VE consultant, and/or develop its own VE training.

(2) Encourage state to use VE by actively participating in VE studies and advising it that VE study costs are eligible (as preliminary engineering costs) for federal-aid participation.

(3) Ensure all applicable NHS projects receive a VE analysis and encourage additional studies of other projects.

(4) Ensure the state has an active VE program and encourage it to include a VECP clause in its construction contracts.

(5) Summarize the state’s VE activity on all federal-aid projects annually and provide the information to the FHWA VE coordinator.

b. FHWA VE coordinator

(1) Promote VE and serve as the technical expert on VE matters for FHWA, state, and local highway agencies.

(2) Provide VE briefings to FHWA, state, and local executives and upper management.

(3) Provide VE training and technical expertise to FHWA, state, and local highway agencies. Assist states to develop VE programs.

(4) Coordinate VE with other FHWA activities aimed at cost reduction or product improvement.

(5) Compile VE activity data received from the division offices and prepare annual report for DOT.

(6) Represent FHWA in VE forums with the U. S. DOT and other federal and state governmental agencies, including membership in SAVE International (formerly the Society of American Value Engineers). Serve as FHWA’s representative to the AASHTO VE Task Force.

9. STATE DOT RESPONSIBILITIES.

a. Each state shall establish a continuing VE program that ensures all applicable NHS projects will receive a VE analysis and provides for the review, approval, implementation, and documentation of the VE study recommendations. Individuals knowledgeable in VE shall be assigned the responsibility to coordinate and monitor the program. States should also develop a VE training program, a tracking and/or record keeping system, and a process to disseminate

and publicize their VE results. This work may include the use of qualified VE specialists on a consulting basis.

b. States should include a VECP clause in their construction contracts to encourage contractors to propose changes in contract requirements which will do the following:

(1) Reduce project cost(s) or improve value or service at no increase or a minor increase in cost.

(2) Provide states with innovative contractor ideas or techniques to be considered when preparing plans, specifications, and estimates on future projects.

The net savings of each proposal should be shared with the contractor at a stated reasonable rate. Reimbursement for such share is eligible for pro rata reimbursement with federal-aid funds. States should retain the right to accept or reject all proposals and acquire all rights to use accepted VE proposals in current and future projects without restriction. An example VECP provision is contained in the AASHTO Guidelines for Value Engineering.

10. USE OF CONSULTANTS. States may employ qualified VE consultants to conduct VE studies on federal-aid projects or elements of federal-aid projects. Consulting firms should not apply VE to their own designs (the law prohibits persons involved in the project from being on the VE team). It is strongly recommended that consultants be qualified VE practitioners, be experienced in performing and leading VE studies (have participated in several VE studies as a team member and as a team leader), and have sufficient VE training, education, and experience to be recognized by SAVE International as meeting the requirements for certification.

11. REPORTING.

a. All VE studies and VECP conducted on federal-aid projects shall be used to prepare an annual VE summary report. At the end of the fiscal year, each division office and/or state DOT will prepare the annual VE summary report and submit it to the FHWA VE coordinator. Reports are due by November 10 of each year.

b. The FHWA VE coordinator shall prepare an annual report including an assessment of the effectiveness of efforts to encourage VE on federal-aid projects to the U. S. DOT by December 10 of each year.

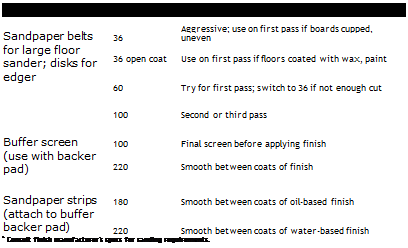

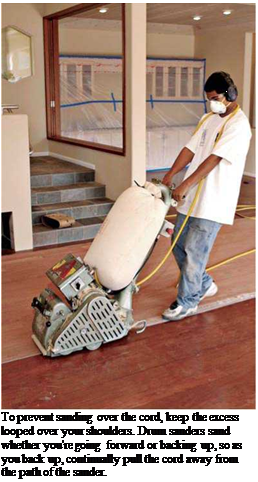

Vacuum the floor so you can survey it closely for nails sticking up, and floorboards that are split or uneven. Use a nail set to sink nails below the floor surface. If boards are uneven or cupping, you may be able to sand them down evenly if they are solid wood. If any boards are split or splintered, replace them now.

Vacuum the floor so you can survey it closely for nails sticking up, and floorboards that are split or uneven. Use a nail set to sink nails below the floor surface. If boards are uneven or cupping, you may be able to sand them down evenly if they are solid wood. If any boards are split or splintered, replace them now.

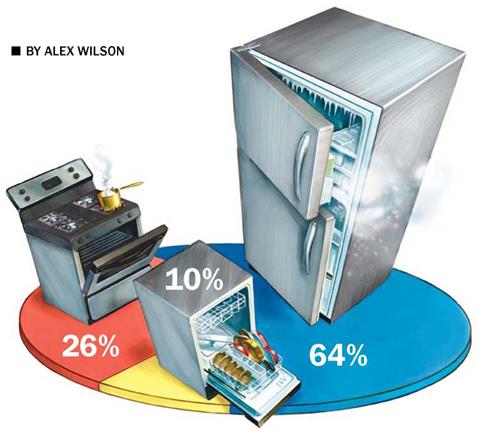

ENERGY STAR

ENERGY STAR

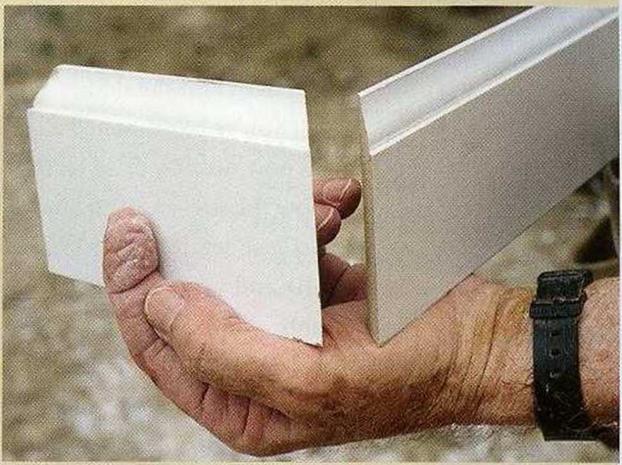

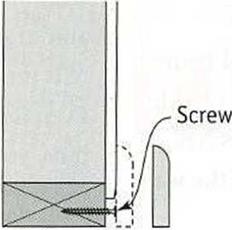

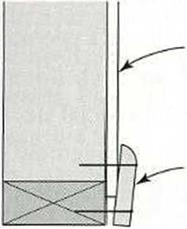

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.

or floor. It is not needed with carpeting because carpeting fills the space between the baseboard and the floor.

or floor. It is not needed with carpeting because carpeting fills the space between the baseboard and the floor.