Value Engineering Change Proposals

As described by AASHTO, VECP programs differ from other VE programs in that the construction contractors develop the recommendations. The contractors choose whether or not to participate, with the incentive for sharing in any cost savings realized. Thus, the states must create and manage a program that will be attractive to the contractors. This program is called by different names in various states, for example, Value Engineering Incentive Provision (VEIP), Value Engineering Incentive Clause (VEIC), and Cost – Reduction Incentive Proposal (CRIP).

A contractor’s participation in a VECP program involves a certain amount of risk. It costs money to search for realistic savings that will be shared by the state, and the contractor cannot expect all proposals to be accepted. However, the program offers an opportunity for contractors to demonstrate ingenuity, innovation, and construction excellence, and to receive financial benefit.

Care should be taken to ensure that a VECP does not compromise any essential design criteria or any preliminary engineering commitments such as environmental mitigation measures. Specific construction elements, such as bridge-span lengths or type of noise barriers, may be excluded from consideration for a VECP, but such exclusions will limit potential savings opportunities. Any exclusions should be delineated in the specifications or other contract documentation.

Benefits. The VECP must not result in impairment of essential functions and characteristics of any part of the project including, but not limited to, service life, reliability, economy of operation, ease of maintenance, desired aesthetics, and safety. The VECP program offers benefits to the state when it (1) enhances the design at reduced cost to the state, (2) results in a net savings over the contract cost, or (3) advances the project completion date. The program offers a low-cost opportunity to use the experience and creative talents of the contractor. Contractors participating in the VECP program take pride in contributing actively to the final development and construction of the project.

Contract Documents. To invite proposals from the contractors, the state should include in the contract document a VECP section, specifically defining basic requirements and evaluation criteria. Before initiating a VECP program, a state may want to secure an interpretation from the attorney general or other appropriate source as to the legality of their VECP provisions. VECP specifications and requirements are described in Section 104.07 of the latest version of AASHTO’s Guide Specifications for Highway Construction (visit the website www. aashto. org for information on how to obtain a copy). In an effort to promote a higher VECP participation, some states are studying the application of the VE job plan (see Arts. 10.3 and 10.4) in facilitated sessions with contractors that can include state employees.

Review Process. The review process for a VECP should include the development of a review schedule to ensure the reviewing agency can meet the contractor’s time frame. VECPs occur during the construction phase of a project and time is usually short. A schedule must be developed for those offices and/or persons who must review and comment on the VECP before final disposition. There should be a single point of contact for each state, to ensure no required office or person is omitted from the review process. The single point of contact also can act to enforce the review schedule. All comments resulting from the review should be compiled and resolved, with a final accept/reject recommendation to management. Proper documentation is essential. Complete and accurate estimates are required for correct savings calculations. The final step in the review process is justification. This is not a trivial step. Timely, accurate notification of all parties involved may reduce confusion and litigation, which also can be avoided by adding language to the state’s VECP provision.

Securing Adequate Contractor Participation. The first step in securing adequate contractor participation is to be certain the VECP program encourages, rather than discourages, such participation. For instance, the sharing percentage must be equitable. The VECP requirements, policies, and procedures should not be so legalistic, stringent, or cumbersome as to discourage contractors from participating, and there should be flexibility to meet changing conditions. Past experience indicates contractors need to be oriented to the VECP program and educated about VE methodology and procedures. A state initiating a VECP program should do what is necessary to ensure an effective contractor orientation and education program is developed and conducted. Otherwise, many contractors probably will be reluctant to participate. AASHTO suggests the following approaches to contractor orientation and education:

• The state should work closely with contractor organizations during the whole of the VECP program planning process. It is important to allow contractors the opportunity to review all elements of the program and provide input. The payoffs from this kind of a joint effort, in contractor support and participation, can be considerable.

• The state should encourage contractors to develop and conduct VE training courses. Where the state is conducting VE training for its own staff, contractor staff also could attend such programs.

• The contractor orientation, education, and promotion program should be a continuing one. Continuing efforts could include regular and periodic distribution of VE information and discussion of VE during preconstruction conferences.

Most of these approaches are obvious, and certainly many others could be developed to fit particular conditions. It is important to provide a well-planned, aggressive, and imaginative contractor VE program to enhance the probability of the success of the VECP effort.

Even though initial contractor participation is secured through this type of promotion, the VECP program will not be successful unless a high level of participation is maintained. AASHTO offers the following considerations for maintaining contractor participation:

• The state must ensure adequate opportunities for participation by providing a broad incentive clause in contractors’ standard specifications.

• Contractors must be assured of a fair and objective evaluation of their proposals. The state should take all reasonable measures to create positive attitudes toward contractor change proposals. It may be beneficial to involve the VE administrator in the day-today VECP.

• Contractors must be assured of timely processing of change proposals. To satisfy this requirement, the state must allocate adequate resources to the program. Additionally, to reduce the time and effort required by a contractor to submit a proposal, the proposal may be submitted first for evaluation. This initial proposal would outline the general technical concepts and the estimated savings.

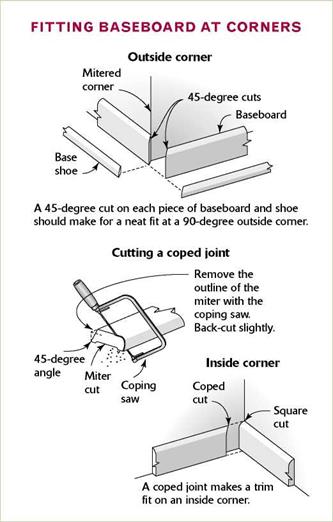

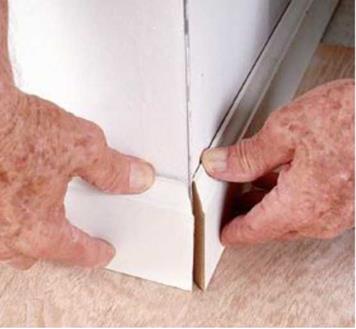

![ATTACHING A COUNTERTOP TO A. BASE CABINET Подпись: Inside baseboard corners are coped. The coped cut fits the profile of the trim piece that runs into the corner. [Photo © The Taunton Press, Inc.]](/img/1312/image822.gif)

SHELVES CUSTOMIZE A CLOSET. Attaching shelves to a closet wall creates more storage space whi*le giving you more flexibility in locating the closet pole.

SHELVES CUSTOMIZE A CLOSET. Attaching shelves to a closet wall creates more storage space whi*le giving you more flexibility in locating the closet pole.

I usually place the two lowest shelves 8 in. and 16 in. off the floor for shoes. For socks and underclothes, I place a shelf every 12 in. above the first two. Fasten corresponding cleats to

I usually place the two lowest shelves 8 in. and 16 in. off the floor for shoes. For socks and underclothes, I place a shelf every 12 in. above the first two. Fasten corresponding cleats to

Figure 9.9 Remains of a tower mill on a hilltop in the northern extremity of Corsica. In this particular case, the unit cannot be turned into the wind (photo by the author).

Figure 9.9 Remains of a tower mill on a hilltop in the northern extremity of Corsica. In this particular case, the unit cannot be turned into the wind (photo by the author).