Irrigation practice in lower Mesopotamia

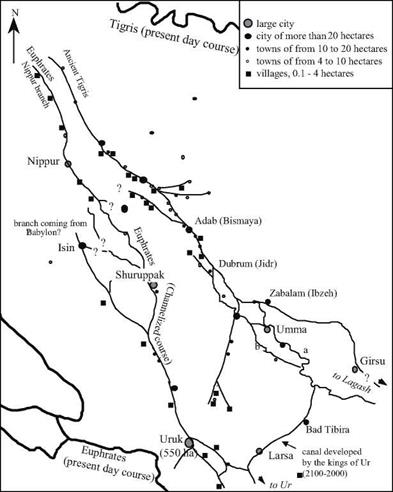

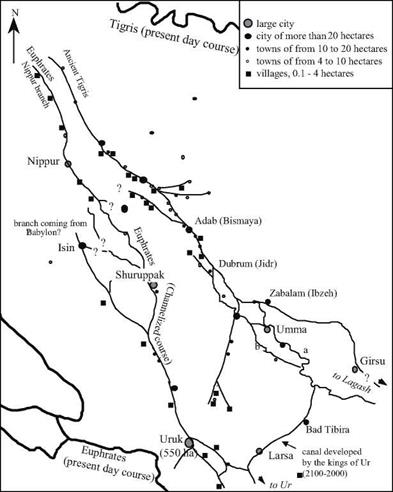

Field studies have shown that the urbanization of the Inrd millennium BC developed along watercourses, whether they were natural river branches or artificial canals. Notable among these studies are those of the American archaeologist Robert McAdams (Figure 2.3). However, it seems likely that at the time of the independent city-states, secondary irrigation canal systems remained essentially local, their layout dictated by the nature of the soil surrounding each city: a band of gardens here, a band of irrigated cereals there. Canals effectively define the boundaries between cities. And of course conflicts over the shared use of water arose along such boundaries. For example, around 2460-2400 BC there was a long dispute between the neighboring city-states of Lagash and Umma. Land concessions in the plain of Gu-edinna, at the boundary between the two cities, were taxed through payments in grain. When water users defaulted on their payments, the irrigation water was simply cut off. It was then necessary to resort to force, as occurred on several occasions

under Eannatum king of Lagash, then later during the reign of his nephew Entemena: “Eannatum, the ishakku (prinice) of Lagash, the uncle of Entemena, the ishakku of Lagash, marked off the boundary with Enakalli, the ishakku ofUmma; led out its (the boundary’s) ditch from the Idnun (canal) to the Guedinna; inscribed (several) steles along that ditch (….) He (Ennatum) levied a tax on them (in compensation for conceded lands) (….) Because this barley remained unpaid – (besides) Ur-Lumma, the ishakku ofUmma deprived the boundary ditch of Ningirsu (and) the boundary ditch of Nanshe of water; ripped out its (the boundary ditch’s) steles (and) put them to fire (….) and (finally) crossed the boundary ditch of Ningirsu – Enannatum fought with him in the Gana-ugigga (where are) the fields and farms of Ningirsu, (and) Entemena, Enannatum’s beloved son, defeated him (….) At that time (however) Il, the temple-head of Zabalam, ravaged (?) (the land) from Girsu to Umma. Il took to himself the ishakku-ship ofUmma; deprived of water the boundary ditch of Ningirsu, the boundary ditch of Nanshe, the Imdubba of Ningirsu, that tract (or arable land) of the girsu tracts which lies toward

the Tigris (….) Entemena (…) made this (boundary) ditch from the Tigris to the Idnun in accor-

2

dance with the straightforward word of Nanshe.

Later on, development and use of the system of large canals saw coordination at a larger scale. Around 1800 BC, the great Babylonia king Hammurabi, who had just united the country, put forth a series of edicts, elements of a civil and penal code.

The prologue of this code notes that in the 33rd year of his reign the sovereign built a canal called “Hammurabi is the prosperity of the people”, designed to supply the Sumerian cities of Nippur, Eridu, Ur, Larsa, Uruk, and Isin. This suggests that the branch of the Euphrates flowing between Nippur and Uruk (see Figure 2.3) had been channelized.

This is also suggested by the proclamation of the 33rd year of the reign: “Hammurabi has dug the canal “Hammurabi is the prosperity of the people” – the canal that is taken care of by (the gods) An and Enlil – and thus provided the cities of Nippur, Eridu, Ur, Larsa, Uruk, and Isin with a steady supply of water for their prosperity and made it possible for the inhabitants of (the lands of) Sumer and Akkad, who had been scattered (by war), to return to their settlements”.

The code of Hammurabi includes edicts that regulate use of the irrigation system. It requires that riverside inhabitants maintain the dikes that protect the fertile lands near the rivercourses, and sets compensatory penalties for those who are remiss in this responsibility:

“If a man has been slack in maintaining [the bank of] his [field] and has not maintained [his] bank and when a breach has occurred in his [bank] and so he has let the waters carry away (the soil on) the water-land, the man in whose bank the breach has occurred shall replace the corn which he has (caused to be) lost.”

“If a man has released the waters and so has let the waters carry away the works on his neighbor’s field, he shall pay ten gur of corn for every bur of land.’0 [35] [36]

|

Figure 2.3 Urbanization of the hydrographic network reconstituted between Nippur and Uruk, around 2500-2000 BC. This map is based on the work of the American archaeologist Robert McAdams. The hydrographic network is reconstructed from (undated!) artifacts of meander fossils and from the juxtaposition of the sites. It was not until the second half of the NIrd millennium BC (end of the ancient Sumerian dynasties and the empire of Akkad) that the rivercourses stabilized, undoubtedly under the influence of the artificial canals. The branch of the Euphrates between Shuruppak and Uruk, in particular, appears remarkably linear and regular from this period on. In the region of Umma, the principal course of the river shifts from (a) to (b) around 2400 BC. The large loop that flows toward the southwest and that supplies Bad Tibira and Larsa was most likely dug by the kings of Ur (2100-2000 BC).4 Uncertain branch locations are shown by “?”.

|

If gravity irrigation is to be used for large-scale cultivation of cereals, either the fields must be below grade compared to the river, whose bed is incised within the natural levees caused by progressive alluvial deposits, or the canal must be constructed on raised fill to bring the water above the level of the fields.

Other texts contain evidence of a hierarchy in canal structure. The river branches or large navigable canals are called, without distinction, id in Sumerian, or naru in Akkadian. Along these narus, intake works supply secondary canals that in turn deliver water to basins called nag-kud in Sumerian or natbaktu in Akkadian. These basins are essentially rectangular reservoirs, varying in length from 12 to 72 m, and 1 to 12 m wide. These natbaktus are built on a plain by means of earthen dikes reinforced with grass or brush, from 1 to 5 m high. These reservoirs, apparently fitted with outlet gates, first provided water storage, but also and importantly made it possible to redistribute water toward raised ditches along the top of small dirt ramparts that carried water into the fields.[37] The irrigation operations involved controlled flooding of fields to be cultivated. After sitting in the field for some time, the water is then drained, leaving the level and damp field ready to be plowed and planted. Once the new plants have germinated, the field is flooded once again, then twice more during the growth of the barley to improve the yield. This gravity irrigation was practiced from the very beginning, as shown in a collection of detailed advice from a Sumerian farmer to his son:

“When you are about to cultivate your field, take care to open the irrigation works (so that) their water does not rise too high in it (the field). When you have emptied it of water, watch the field’s wet ground that it stays even.. ,.”[38]

We also have direct external testimony, albeit delayed, of these irrigation works from Greek travelers. Perhaps in trying to understand the origin of war, Herodotus of Halicarnassae, a Greek citizen of the Persian Empire, traveled the known world following the Median wars during which the Persians burned Athens. Around 460 BC he visited Egypt and Mesopotamia. Here is what he wrote about irrigation practices in the Babylonian region:

“Very little rain falls in the land of Assyria, and this little is what nourishes the root of the crop; but it is in its watering from the river that the corn crop wins to its ripeness and the bread grain comes into being. It is not as in Egypt, where the river itself rises over the fields; in Babylon the watering is done by hand-operated swing beams.”[39]

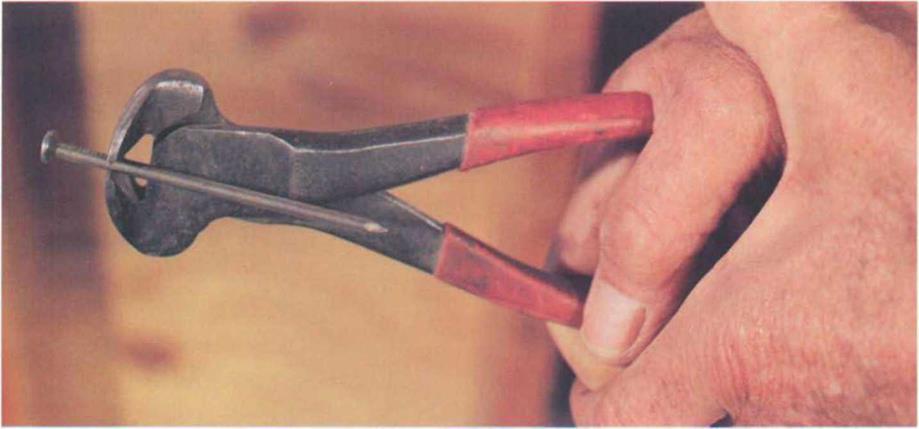

This text illustrates a second irrigation method – lifting of water to the crops to be irrigated. The technique was probably used only for small-scale agriculture on the marshes. The “machine” most often used in this period was the shaduf a balance beam provided with counterweights (Figure 2.4). Its use appeared in Mesopotamia in the IVth millennium BC, and likely migrated into Egypt in the beginning of the IInd millennium BC.[40]

The system relied on muscle power, but it was simple, efficient, and easy to maintain. It became a permanent feature of traditional irrigation techniques of the Near East.

opposite, illustration from 1885 (Poillon, ancient archives of the Ecole Nationale des Ponts et Chaussees ENPC)

opposite, illustration from 1885 (Poillon, ancient archives of the Ecole Nationale des Ponts et Chaussees ENPC)

Another traveler, somewhat less of a passive observer than Herodotus, was Xenophon, a former student of Socrates. In about 400 BC, he joined in the adventure of an army of mercenary Greeks, the Ten Thousand, hired to support the revolt of a prince within the Achaemenids royal family. After the death of the prince and his generals, it was Xenophon who had to lead the difficult retreat. He crossed numerous canals between the Euphrates and the Tigris, a bit to the north of Babylon:

“…crossing on their way two canals, one by a stationary bridge, and the other by a bridge made of seven boats. These canals issued from the Tigris river, and from them, again, ditches had been cut that ran into the country, at first large, then smaller, and finally little channels..”[41]

The irrigation principles of lower Mesopotamia were followed beyond the end of the Persian Empire of the Achaeminides. In the lowest areas of the plain, where the silts deposited by the two rivers caused the soil to be cohesive and sticky, constant work was necessary to keep the network in good operating condition. Later on, around the beginning of the modern (i. e. Christian) period, the Greco-Roman geographer Strabo writes: “Now this is the origin of the canals; but there is need of much labor to keep them up, for the soil is so deep and soft and yielding that it is easily swept out by the streams and the plains are laid bare, and the canals are easily filled, and their mouths choked by the silt; and thus it results again that the overflow of the waters, emptying into the plains near the sea, form lakes and marshes (….) And indeed there is also need of quick work in order to close the canals quickly and to prevent all the water from emptying out of them. For when they dry up in the summer, they dry up the river too; and when the river is lowered it cannot supply the sluices with water at the time needed, since the water is needed most in summer, when the country is fiery hot and scorched; and it makes no difference whether the crops are submerged by the abundance of water, or are destroyed by thirst for water.”[42] [43]

We will see in Chapter 7 that this delicate equilibrium is not sustainable, though this does not become apparent for several centuries to come. Even so, a large canal will be built parallel to the Tigris and on its left bank (the nahr Awan), departing from the river at a point situated 24 km upstream of Samarra (about a hundred kilometers upstream of the present-day Baghdad), and terminating about a hundred kilometers southeast of Baghdad, collecting the waters of the Diyala along its way. It will be completed in the sixth century AD under the reign of the Sassanide sovereign Khusraw I.11

![]()

opposite, illustration from 1885 (Poillon, ancient archives of the Ecole Nationale des Ponts et Chaussees ENPC)

opposite, illustration from 1885 (Poillon, ancient archives of the Ecole Nationale des Ponts et Chaussees ENPC)