Hydraulic development involved not only the digging of canals, but also the restoration or maintenance of river courses. During the domination of Larsa in lower Mesopotamia (1932 to 1763 BC), it became necessary to rehabilitate the river system. The king Sin – Iddinam reestablishes the course of the Tigris, around 1845 BC, using paid labor:

“When An, Enlil, Nanna and Utu (Sumerian gods) blessed me with a good reign of justice and long days (…), to obtain fresh water for the cities of my country, (…), I fervently prayed to An and Enlil. They answered my fervent prayers and, by their absolute orders, charged me with the mission to dredge out the Tigris, to restore it (into its previous state) and to give the days of a long life to my name. So (…) I grandly dug out the Tigris, the river of abundance of Utu. I raised the top of the slope, the old embankment (…); I transformed the Tigris into a freely flowing water; I established at Larsa, in my country, an eternal source of water, a never-ending abundance. When I dredged the Tigris, the great river, the wages of each worker were 3 ban (?) of Barley, 2 sila of bread, 4 sila of beer and 2 sicles of oil: this they received each day; nobody received more or less. With the strength of my country, I brought this project to a good end. With the reins and the decrees of the great gods, I restored the Tigris, the vast river, and I affirmed my good name for the far distant future.”[47]

A succession of kings of Larsa, in particular Rim Sim who was the last, dredged and reestablished all the fluvial system from Lagash and Larsa down to the sea. This rehabilitation included the large branch flowing to the southwest on Figure 2.3 that supplies Bad Tibira and Larsa; this loop had been dredged earlier by the kings of Ur.

The floods of the Tigris and Euphrates, out of phase with the growing cycle of the grains, are more of a menace than a blessing. We know that the dikes or levees protect the cities and crops against floods, and stabilize the course of the rivers to the extent possible. At Babylon, major works were accomplished to this end. Herodotus attributes these works to two queens:

“The first ruled five generations before the second; her name was Semiramis, and she built those dikes on the plain that are so remarkable to see; before that, the river used to run all over the plain and flood it.”[48]

In the eyes of the Greeks, Semiramis is a veritable legend. According to Georges Roux, Semiramis is possibly Sammuramat, an Assyrian queen who occupied the throne around 800 BC. All of the works mentioned herein (and especially the works described below) can also, according to Georges Roux, be attributed to the queen Naqia, the widow of Sennacherib. It is in fact eleven years after the destruction of Babylon by Sennacherib, a destruction that was considered to be a sort of sacrilege, that the son of Sennacherib undertakes the reconstruction of the city (this then puts us in 678 BC). But the biggest astonishment remains to come; let us once again listen to Herodotus:

“The second of these queens was called Nitocris (….) First, then, as to the Euphrates, which flows right through the middle of the city of Babylon. Formerly it was straight, but she made it so crooked, by digging canals above the city, that the river in its course comes three times to one of the Assyrian villages (….) This is what she did, she built an embankment along either shore of the river that is, in greatness and height, very wonderful in its dimensions. Far above Babylon she dug a basin for a lake, stretching it by the side of the river and a little away from it, and in depth she dug it always down to find water, and in breadth she made the circuit of the lake to be fifty-two and a half miles (84 km) (….) She did both of these things – the making the river crooked and turning the basin into a marsh – so that the river might be slower, as it was broken by the many bends, and that the courses into Babylon itself might be crooked, and that then, after this, should come the long circuit of the lake. These works were built at precisely the point of her country where were the passes of entry and the shortcuts from the road out of Media, so that the Medes might not get into contact with her people and learn of her affairs.

”With these defenses she surrounded her city, but she added another work that grew out of them (….) For when she had dug the basin of the lake (….) she had huge stones cut, and when the stones were ready and the basin had been dug, she turned the entire stream of the river into the place that was dug. While it was filling, the old riverbed dried out; and she bricked with baked bricks, in fashion like to the walls, the banks of the river in the city and the descents from the gates leading down to the river (….) When the dug part had become a lake, filled by the river (…) she turned the Euphrates into its old course..”

This is a fine example of river engineering. According to recent work by Charpin (2002), the artificial lakes and dikes might in fact have been built by Samsuilina 17491712 BC, the successor of Hamurabi. If the account is correct, cut stone blocks were used for the difficult operation of blocking the river to divert water into the artificial lake. It is interesting to consider the roles of the meanders and the lake. The meanders effectively reduce the slope of the river, since the same drop is attained over a greater length. If the width and discharge remain the same, one can estimate that reduction of the slope by a factor of two, over a long length, will reduce the current velocity a little less than 25%, and raise the water depth in about the same proportions. Therefore it becomes necessary to raise the dikes. The lake, located upstream of the city, very likely plays a role in attenuating floods, capturing excess water through overflow when the river rises above a certain level.

The accounts of Herodotus include other examples of the Mesopotamian know-how in river course modification. Cyrus, the founder of the Persian Empire, suffered the loss of one of the sacred white horses of his team when crossing the Diyala (Gyndes to the Greeks). Furious at this affront to his power, he put his entire army to work for a full year (according to tradition) to break down the Gyndes into 360 small canals. Herodotus also reports that Cyrus (in 539 BC) enters Babylon without resistance using the hydraulic works described above:

“When he came to the lake, Cyrus dealt with it, and with the river, just as the Babylonian queen had done; he directed the river by a canal into the lake, which had become a marsh, and so, when the river had sunk, its old stream became fordable.”[49]

Once he had entered the city itself, Cyrus further extended the armoring of the banks. He didn’t miss the chance to commemorate this feat in carving the following inscription: “I added to (..) the banks protected by bricks, in the low-lying areas of the city, that a pre-

|

і o

vious king had begun to build…”

Figure 2.5 The Euphrates and the Babylonian canals (after Margueron, 1991).

|

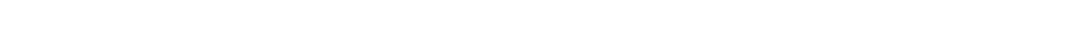

Directly above a bathroom, this attic view reveals a dropped soffit and a large plumbing chase for the vent stack. The soffit connects the attic with the walls; the plumbing chase is a direct hole running through the house. These two leaks are like leaving a window open. The Fix: Cover the open framing with rigid foam or plywood, and seal small openings with spray foam. Finally, cover them with insulation. Loose-fill insulation such as cellulose is cheap and easy to install.

Directly above a bathroom, this attic view reveals a dropped soffit and a large plumbing chase for the vent stack. The soffit connects the attic with the walls; the plumbing chase is a direct hole running through the house. These two leaks are like leaving a window open. The Fix: Cover the open framing with rigid foam or plywood, and seal small openings with spray foam. Finally, cover them with insulation. Loose-fill insulation such as cellulose is cheap and easy to install.

![]()

Block planes shave off tiny amounts of wood from door edges, casings, and other thin stock, allowing tight, final fits of materials.

Block planes shave off tiny amounts of wood from door edges, casings, and other thin stock, allowing tight, final fits of materials.

Bullnose planes can fine-shave wood edges in tight places. Bullnose blades are the same width as plane shoes. You can remove the bullnose front piece, allowing you to plane right up to the juncture of an adjoining piece.

Bullnose planes can fine-shave wood edges in tight places. Bullnose blades are the same width as plane shoes. You can remove the bullnose front piece, allowing you to plane right up to the juncture of an adjoining piece.

a When working in wet weather, wipe the tape dry with a cloth before reeling it into the case. Moisture inside the tape case can

a When working in wet weather, wipe the tape dry with a cloth before reeling it into the case. Moisture inside the tape case can

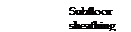

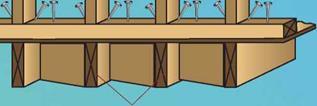

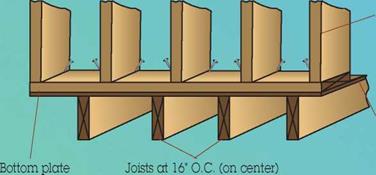

If wall sits on a rim joist or blocking, place third nail at center of joist space and nail into rim or block.

If wall sits on a rim joist or blocking, place third nail at center of joist space and nail into rim or block.