Choosing a site that avoids hazardous pollutants and then building with healthy materials are vital for creating a healthy home. The naturally occurring Earth energies, known as geopathic stress, are another important factor to consider. These energies result from polar magnetism, underground domes, veinsand streams of water, radon gasemis – sions, electromagnetic waves, and seismic activity. Their effects can be seen in rockfaufts, fissures and geological stresses, power spots, vortices, mineral and ore deposits, and underground caves.

Their health effects can range from subtle to severe, with some being well accepted and others less recognized and sometimes controversial. California prohibits new construction over earthquake faults, and the US Environmental Protection Agency recommends that all homes be checked for radon gas emissions. Switzerland and Germany have mandated testing for geopathic stress before hospitals, schools, and multifamily dwellings are constructed.

Increasingly, the human body is also subjected to the effects of artificially produced electromagnetic forces. These result from mining, building foundations, excavations, underground transportation, sewers, water pipes, communication

systems, electrical generation, and transmission infrastructure as well as microwaves, satellites, radar, cell phones, and wireless technologies.

In the 1940s, German researchers Ernest Hartmann and Manfred Curry identified a tightly woven network of magnetically charged, naturally occurring energy lines crisscrossing the Earth and penetrating buildings. When geopathic stress is combined with human-caused stress conditions over a prolonged period of time, our health can be profoundly affected.

Our five senses pick up an infinitesimal part of the spectrum of information about these stresses. In the past, known locations with high levelsof nat- urallyoccurring harmful Earth forces wereavoided. Indigenous people were aware of places where subtle energies supported the abundant growth of plants and trees and the health of animals. We are all familiar with special places that make usfeel comfortable, warm, or inspired. Similarly, when we walk into other spaces we become disturbed, cold, or restless. Overtime, the places where we live and work will have an impact on our health.

Our understanding of these subtle health effects is growing. According to the Dulwich Health Clinic in London, geopathic stress is present in

problems may be costly. Industrial toxins in the soil, poor percolation for installing a septic system, and unstable soils are examples of conditions that might be causes for concern. We recommend that you make your offer to purchase contingent on inspections by professional consultants. In this way you can prevent being obligated to purchase a contaminated or otherwise unacceptable site. The following sections describe some of the more common consultant specialties.

Phase I Environmental Inspector

If you are considering a property with a past of industrial or agricultural use or underground fuel tanks, or if old buildings are suspected of containing lead or asbestos, then a Phase I environmental audit should be conducted to

people with most types of serious and long-term illnesses. "Geopathic stress does not cause any specific type of illness but lowers your immune system and your ability to fight off viruses and bacteria."9

In 1989, Otto Bergsmann found measurable changes in levels of serotonin, melatonin, calcium, and zinc when a person was subjected to noxious Earth energy emissions.13 Hans Nieper concluded that the incidence of cancer was higher over geopathic zones: "Geopathic zones increase the risk of gene lability," or genetic errors. He strongly advised those suffering from these ill effects to remove themselves from the site of geopathogenic exposures

Kathe Bachler has linked children’s poor school performance to geopathogenic "interference zones."d After investigating noxious geopathic lines and chronic fatigue syndrome in 14,000 cases, Alf Riggs concluded that geopathic stress is a major factor in 72 percent of cases of the syndrome and that measurable improvement occurred when a patient’s bed was moved to a neutral location. There was even more improvement when a wooden bed was substituted for a metal bed and mattress springs. e

Other physical indicators have included:

• sleep disorders (strong resistance to going to bed, insomnia, nightmares, sleepwalking, sweating, cold/shivers, waking feeling tired/ unrested, waking feeling nauseous)

• an aversion to lying in certain spots in one’s bed

• experiencing a feeling of falling out of bed

• depression, stress, rapid heart rate, or cramps

Some physicians suggest that, if symptoms do not respond to normally successful treatments, Earth energies may exist in their patient’s home.

Conventional electronic scientific instruments can be used to indicate zones of geopathic stress by measuring parameters such as conductivity of the ground and air, DC magnetic fields, changes to air ionization, ground temperature, above-normal soil or air humidity, and seismic activity. These sophisticated instruments are expensive and not generally usable by the public.

Plant life and animal behavior can indicate areas of geopathic stress. Cats, bees, and ants are drawn to these areas. Cattle, horses, sheep, pigs, swallows, chickens, and dogs avoid them. In traditional cultures, animals were herded onto building identify the risks. Remember that up-front costs are minor compared to hazardous waste cleanup costs, which may far exceed property value.

Geotechnical Consultant

If you are concerned about the geological structure of the site, you should consult with a geotechnical engineer, who will be able to troubleshoot problems such as high water tables, unstable soils, expansive soils, earthquake faults, and sink holes. Engineering solutions can be devised for many of these problems so that the costs of development can be determined before you purchase the land.

Septic Engineer

In many locations where municipal sewers are not available, an engineered septic system plan is required before a building permit will be issued. The septic engineer, who is often a geotechnical engineer as well, will study the

sites and their behavior was observed to ensure avoidance of geopathic stress. Oak, ash, elm, and willow trees thrive in areas of high geopathic stress whereas fruit trees do not. Trees can also be observed to see if they lean, twist, or grow knurls.

Lightning has been reported to strike where underground water veins cross and geopathic stress appears to be more prevalent in areas of exposed fractured igneous or sedimentary rock and less common in areas with a thick overburden of gravel or soil. Clay soils seem to accentuate the stress. Even observation of buildings can be useful since cracks, moisture, mold, crumbling plaster, discoloration and damaged materials in existing construction, and patterns of alignment or deterioration of stone, masonry, concrete, or pavement correspond to areas of geopathic stress and can indicate its presence.

For centuries, dowsers or diviners have located water veins, energy grids, and points of elevated energy (power spots). Levels of skill and techniques for assessing, locating, and correcting these forces vary considerably, but results are reported to be consistent among experienced practitioners.

Geopathic stress can be reduced or reversed, but the most important corrective measure is avoidance. Architects and designers should take land energies into account and avoid them when siting buildings. In its top 25 principles, Building Biology considers geobiology in the process of selecting building sites and materials. It recommends avoiding certain materials such as steel structural frames, metal furniture, electrical wiring, and ductwork, which conduct and transmit Earth energies throughout a building.

Various correction techniques and devices have been proposed. Individual research and testing by experienced practitioners is recommended to ensure that any corrective measures are effective and do not have any unhealthy consequences.

Choosing building sites with a balanced quality can positively influence our health. It is not a good idea to spend extended time in negatively stressed areas or to inhabit places of high energetic activity. Pay attention to how you feel on a potential building site. Applying information about Earth energies known from ancient universal practices will have a profound effect on our health and well-being in our homes and workplaces.

Further information:

land formation and perform percolation tests to determine how the sewage waste projected for your development can best be handled. In areas with limited percolation, steep slopes, or high water tables, the installation of a proper septic system could be costly or even impossible. If such conditions exist, it is best to be informed prior to purchasing the land.

Duration of

Duration of 0

0

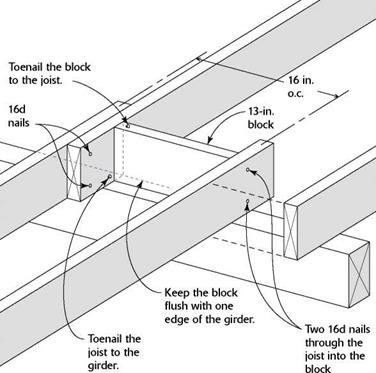

Starter courses can be three-tab shingles with the bottom 5 in. cut off or a starter strip that comes on rolls in various widths. Starter strips have the advantage of stiffening shingles above and, viewed from below, providing a clean, unbroken line. Still, trimming three-tab shingles is cheaper, so here’s a quick look at that method.

Starter courses can be three-tab shingles with the bottom 5 in. cut off or a starter strip that comes on rolls in various widths. Starter strips have the advantage of stiffening shingles above and, viewed from below, providing a clean, unbroken line. Still, trimming three-tab shingles is cheaper, so here’s a quick look at that method.

7. Start second row with half sheet so ends will be staggered.

7. Start second row with half sheet so ends will be staggered.