REPOINTING MORTAR JOINTS

Even materials as durable as brick and mortar break down in time, most commonly near the top of a wall or chimney, where masonry is most exposed to the elements. Often, the structure wasn’t capped or flashed properly. If the bricks are loose, remove them till you reach bricks that are solidly attached. If joints are weathered but bricks remain firmly attached, repoint (or tuck-point) the joints by partially cutting back the mortar, adding new mortar, and shaping the joints. If the brick is painted, see "Stripping Painted Brick,” on p. 191.

Finally, if vertical or diagonal cracks run through several courses, there may be underlying structural problems, which must be corrected before repointing. In this case, consult a structural engineer.

Raking old mortar. For best results, rake out (scrape out) mortar joints in an inconspicuous area as a test, starting with the least destructive tool. If the mortar is soft enough, an old screwdriver may be all you need. But if the mortar is as hard as the brick, you’ll need to be patient. Cut

FOR RAKING MORTAR

Before you can repoint joints, you must rake (cut back) old mortar, preferably without damaging surrounding brick. You’ve got several options:

► TUCK-POINTING (PLUGGING) CHISELS are usually thinner than mortar joints. Used with a 2-lb. hand sledge, they’re slow but exact.

► ANGLE GRINDERS with an abrasive wheel cut quickly into old mortar, but they can easily damage soft brick and leave a ragged line.

► PNEUMATIC AIR CHISELS represent a good balance of speed and control, but you’ll need to special-order mortar-removal bits. Trow & Holden (Barre, VT) offers a set that includes Vin. and V4-in. cape chisels, a V4-in. swept cape chisel, and a 4-tooth ripper. Wear safety glasses and a respirator mask when cutting mortar.

![]() joints 1 in. deep, and try to cut a square trough (not a V-groove) in the old mortar.

joints 1 in. deep, and try to cut a square trough (not a V-groove) in the old mortar.

Once you’ve raked the joints to the correct depth, brush them out well, using a whisk broom or a wallpaperer’s brush, which you can also use to wet down the joints before adding fresh mortar. Remove debris with an air hose or a heavy-duty vacuum. Of course, wear safety glasses and a respirator mask for this work.

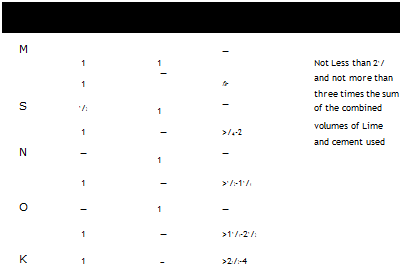

The mortar mix. Try to match the old mortar mix when repointing an older brick building. Before portland cement was widely used, mortar joints were usually a resilient mix of hydrated lime and sand, which compressed slightly as the bricks expanded during summer and expanded slightly as the bricks contracted during cool weather. Soft, lime-rich mortars also show autogenous healing, an ability to self-repair hairline cracks caused by seasonal temperature shifts. Mortar joints with portland cement, on the other hand, are relatively hard and inflexible: As old bricks heat up, they have no room to expand, so they crack and spall (flake).

Although mortar analysis is the best way to match old mixes—historic preservation agencies can suggest mortar analysts—type О mortar (described earlier in this chapter) should be a close match for most old mortars. For this, mix 1 part portland cement, 2 parts hydrated lime, and 8 parts fine sand. The mix should be fairly stiff as mortar mixes go, keeping its shape when squeezed into a ball. If the mix becomes too stiff to work, periodically sprinkle on and stir in small amounts of water.

If you’re repointing only a section of a structure, however, and don’t want it to stick out like a sore thumb, experiment with combinations of mortar dye, cement, sand, and lime, carefully labeling the proportions of each batch and allowing it dry for a month before committing to a recipe. Masonry supply houses stock such materials; they also carry new bricks manufactured to look old, should you need to replace bricks as well.

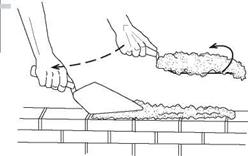

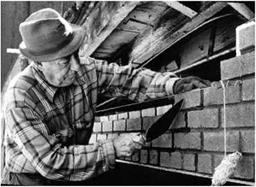

Repointing technique. Using a spray bottle or a brush, dampen the newly cleaned-out joints before applying fresh mortar. There are two ways to fill joints with new mortar. If you’re repointing a relatively small area, use a bricklayer’s trowel as a palette for the mortar and a tuck-pointing trowel to push the mortar into the joint. (See the photo on p. 198.) Press the mortar firmly, so that it will stick.

![]()

If you’re repointing a large area, use a grout bag to squeeze the mortar into the joint. A grout bag looks like the pastry bag used to dispense fancy icing onto cakes. You force the mortar out by twisting the canvas bag. But you’ll need strong

If you’re repointing a large area, use a grout bag to squeeze the mortar into the joint. A grout bag looks like the pastry bag used to dispense fancy icing onto cakes. You force the mortar out by twisting the canvas bag. But you’ll need strong

hands and forearms to twist the filled 5-lb. to 10-lb. bag. And you may need to thin the mix slightly so it will flow easily through the bag.

After using a grout bag, you’ll still need to tuck- point the mortar joints.

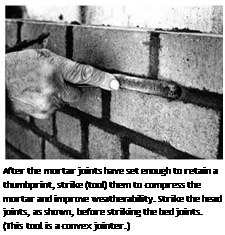

When the mortar has dried enough to retain the imprint of your thumb, tool the joints. In most cases, use a jointer that creates mortar joints the same shape as the old ones. Point the head joints first, then the bed joints. As you work, use a trowel to clean the mortar from the brick faces, but don’t disturb the mortar joints. Then wait 2 hours or 3 hours before using a stiff plastic-bristle brush to remove the mortar still stuck to the brick faces.

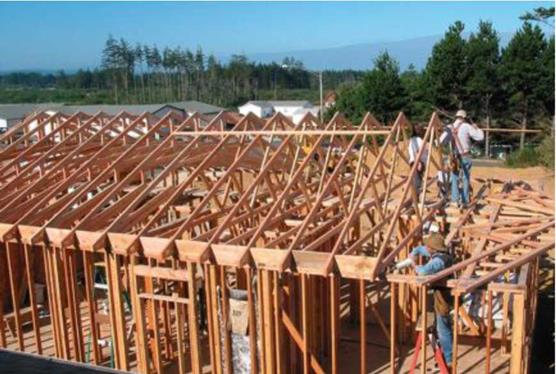

Rolling roof trusses. The first truss you should nail in place is the one for the gable end. Then it’s just a matter of rolling the remaining trusses in place, setting them on their layout marks, and nailing them down. You can do this while standing on the walls or by working off a ladder. [Photo by Don Charles Blom, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]

Rolling roof trusses. The first truss you should nail in place is the one for the gable end. Then it’s just a matter of rolling the remaining trusses in place, setting them on their layout marks, and nailing them down. You can do this while standing on the walls or by working off a ladder. [Photo by Don Charles Blom, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]![. . Spreading the trusses Подпись: Making gable-end notches. Whether you're installing trusses (see the photo below) or traditional rafters and ridge boards (see the photo above), the gable-end rafters require notches every 4 ft. to hold the lookout boards that support the barge rafter. Each lookout butts against the face of the closest inboard rafter, where it's nailed fast. [Top photo © Larry Haun; bottom photo © Roger Turk]](/img/1312/image389.gif)

■ BY MATTHEW TEAGUE

■ BY MATTHEW TEAGUE

Vinyl

Vinyl

TWO WAYS TO CUT BRICK

TWO WAYS TO CUT BRICK