|

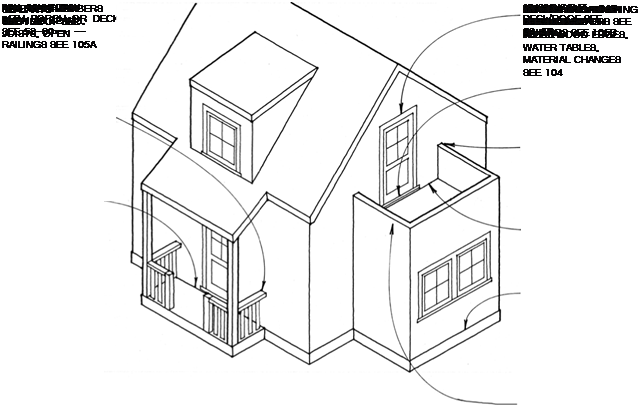

Many of the demonstration projects used trusses and several used the simplified trim details described above. However, several projects also used vaulted ceiling rafter framing to provide more open space in relatively small homes. In some houses the vaulted ceilings provided lofts and expandable space.

|

|

Lincoln, Nebraska

|

Karl Witt used vaulted ceilings with clerestory windows in the living area of his homes. This provided a degree of passive solar heating and natural lighting.

|

|

Everett, Washington

|

Vaulted ceilings with clerestory windows and open soffit overhangs were used in Everett.

|

|

Mesa County, Colorado

|

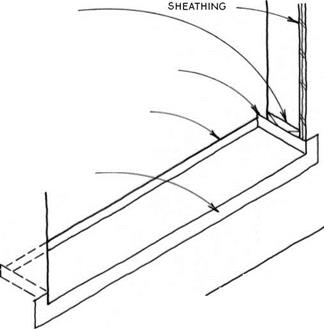

Instead of the more typical 1/2-inch plywood roof sheathing, Roger Ladd used 3/8-inch plywood with metal plyclips.

|

An excellent opportunity exists to reduce construction costs through innovative plumbing. But plumbing is also one of the more difficult areas to get innovations adopted. In spite of the fact that present model plumbing codes are updated periodically, the process is lengthy and uncertain, so none of the model codes reflect current state-of-the-art.

In addition, comprehensive model plumbing codes cover all types of buildings and are overly complex for dealing with relatively simple requirements of single family dwellings.

The four major model plumbing codes are the BOCA Basic Plumbing Code. the SBCC Standard Plumbing Code, the NAPHCC National Standard Plumbing Code, and the ІАМРО/ ICBO Uniform Plumbing Code.

Many local jurisdictions use one of the model codes with their own modifications. In almost all cases, local modifications are more restrictive in material and design than the parent model code.

Confronted with these facts, the NAHB National Research Center has compiled a state-of-the-art manual for residential plumbing. This effort, sponsored by NAHB and HUD, resulted in Residential Plumbing Guidelines which contains all requirements to assure a safe, functional, durable, and cost – effective residential plumbing system. NAHB submitted proposed code changes to the Council of American Building Officials (CABO) in 1984, and the proposed changes were adopted in January, 1986.

Substantial changes were made in some areas of the code. Following is a synopsis of the more relevant changes that affect the installed cost of plumbing.

The load on the drain, waste, and venting (DWV) system is determined by drainage fixture unit (d. f.u.) values.

This is a measure of the probable discharge into the drainage system by various types of plumbing fixtures and is used to size DWV piping systems.

The newly adopted d. f.u. values are, in every case, less than those in the old CABO code. The old values are basically the same as those used in the other major model codes.

The new CABO code includes d. f.u. values for plumbing fixture groupings. These values are less than the sum of individual fixture units, which recognizes the fact that d. f.u. values are not additive when the probability of simultaneous use is very, very low.

The new CABO code allows 75 foot spacing of cleanouts versus 50 foot spacing in the old code. This is consistent with standard available snake lengths.

The new CABO code allows smaller size traps and trap arms for some fixtures. Below-grade drain pipe mini mums were reduced from 2 to 11/2 inches in diameter because of power driven cleanout equipment capabilties.

In practice, large diameter drain pipe is often perceived to be desirable. However, with the lower discharge rates of modern residential fixtures manufactured to water conserving standards, large diameter drains have very low flow rates which promote deposition of solids.

Smaller diameter pipe with higher flow rates actually provides improved transport characteristics. This is a classical case where bigger is not necessarily better and where traditional thought is outdated.

The new CABO code allows an increase in maximum trap arm lengths. This provides a degree of architectural flexibility such as the location of kitchen sinks under windows.

The purpose of the venting system is to maintain atmospheric pressure within the DWV system and to provide venting of gasses by circulating air throughout the system. At low flow rates, characteristic of residential construction, vent pipes need only be of small diameter. In addition, vents need not penetrate the roof. Rather, vents can extend through an exterior wall or roof overhang and terminate downward.

According to the new CABO code, "A common vent may be used for two waste fixtures connecting at different levels in the stack but within the same branch interval, provided the vertical drain is one pipe diameter larger than the upper fixture drain, but in no case smaller than the lower fixture drain. The vertical piping between fixture connections serves as a wet vent for the lower fixture." (Section P-2207.7.1, One and Two Family Dwelling Code).

The CABO code also states, "Stack venting, with certain preconditions relating to drainage loads and ventings, fitting types and sizes, and placement of connections, shall be permitted as a system that allows fixtures and fixture group to be independently connected to a soil or waste stack without individual fixture venting." (Section P-2207.8, One and Two Family Dwelling Code).

The significance of these paragraphs cannot be overlooked inasmuch as the total cost of plumbing DWV in an average home can be reduced substantially. When combined with other DWV innovative practices, total costs have been reduced by as much as $400, depending on which code was used as the comparison.

Because of this (and the fact that the techniques have been proven for many years to be safe and reliable), it will be well worth while for builders to push for adoption of the plumbing section of the CABO code.

Water Service As with DWV piping, water service

and Distribution requirements in the CABO code have

been changed significantly toward cost reduction and efficiency. Health standards have been maintained in all cases.

In all major model codes acceptable water service pipe materials include copper, galvanized steel, PVC or CPVC plastic, polyethylene plastic, and polybutylene plastic. Some local codes are more restrictive, especially in use of plastic pipe.

The lack of competition in materials often tends to keep the cost of the only acceptable materials high. If for no other reason, a variety of acceptable materials is desirable.

Section P-2405.3 in the new CABO code, individual fixture stops are considered optional for single-family housing. Experience has shown that individual fixture stops often deteriorate between time of installation and time of their eventual use to the degree that they may require service or replacement. They also create potential sources of leaks. This is a case where possible convenience is offset by more probable inconvenience. ‘ In any case, convenience items should not be codified.

Water supply fixture unit (w. s.f. u.) values have been changed in the new CABO code and are consistent with established values in fitting standards. The new w. s.f. u. values for both hot and cold water provides for selection of pipe sizes based on reasonable estimates of peak demands. Measurements made m numerous field and laboratory tests have confirmed these values.

Minimum size offixture water supply pipes for all fixtures, except dishwashers and lavatories, is 3/8 inch in the new CABO code. For dishwashers and lavatories, minimum size is 1/4 inch. Fixture group main minimum sizes are either 3/8 inch or 1/2 inch, depending on number and size of fixture branch pipes connected.

The CABO code also recognizes the different flow rates of different pipe materials and the w. s.f. u. values vary accordingly. Therefore, supply pipe often can be reduced in size depending on the number and type of fixtures.

The significance of the new CABO One and Two Family Dwelling Code cannot be overemphasized. Studies have shown a total cost reduction in supply piping of as much as 24 percent even when the same piping material is used.

For more information on the innovations discussed herein, write the Council of American Building Officials, 5203 Leesburg Pike, Suite 708, Falls Church, VA 22041.

There are methods to reduce plumbing costs regardless of code restrictions. Some may require negotiating with the plumbing subcontractor to get full benefit, others may require market evaluation to determine consumer acceptability.

There are methods to reduce plumbing costs regardless of code restrictions. Some may require negotiating with the plumbing subcontractor to get full benefit, others may require market evaluation to determine consumer acceptability.

Cluster the plumbing. This cost-saving design principle is to arrange plumbing groupings back-to-back in a common wall and to shorten distances of other plumbing runs as much as possible. In multiple-story buildings, fixtures should be located over each other to minimize DWV and supply piping. Savings can amount to as much as 10 percent. Plumbing subcontractors often bid on a "per fixture" basis so the value of clustered plumbing may not be passed on without negotiation.

White plumbing fixtures are less expensive than colored fixtures. A savings of $40 to $75 per bath can be realized. From a consumer standpoint, any accent or decorating color can be used with white fixtures.

Consider fiberglass bathing modules. They often are less expensive than other bathtub/shower materials.

Wall hung lavatories can reduce costs although vanities have become standard. Wall hung units may be a marketing problem, but they should be considered, especially in powder rooms and/or second bathrooms.

Size water heaters according to intended use. Smaller homes intended for small families do not need large water heaters. Thirty-gallon gas or 30- to 40-gallon electric water heaters are generally adequate. Also, water heaters with a five-year warranty cost about $20 less than units with a ten – year warranty. This reflects an lV additional five-year insurance policy, not the basic construction of the water heater.

Consider polybutylene supply piping. This material is flexible and, therefore, requires only about 1/3 the number of fittings as rigid pipe materials. It normally costs much less to install and has some advantages in flow characteristics.

Field studies have shown cost savings of between 30 and 50 percent.

There are methods to reduce plumbing costs regardless of code restrictions. Some may require negotiating with the plumbing subcontractor to get full benefit, others may require market evaluation to determine consumer acceptability.

There are methods to reduce plumbing costs regardless of code restrictions. Some may require negotiating with the plumbing subcontractor to get full benefit, others may require market evaluation to determine consumer acceptability.