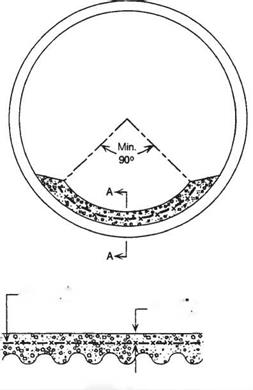

Where high embankments are placed on original ground, the fill may compress and consolidate the foundation soil. Thus, culverts constructed on or near the original ground surface tend to undergo some settlement. The amount of settlement varies with fill height and the consolidation characteristics of the foundation soil. Because the amount of settlement varies with the fill height, the culvert will tend to settle more toward the center than at the ends. If the culvert is built upon a straight grade between the inlet and outlet elevations, a sag will develop. The sag may create a low point in the culvert, or may cause accumulation of debris and silt and opening and leaking of joints. These in turn may lead to a reduced waterway capacity and the possibility of loss of stability to the embankment through piping of fines at the joint. As illustrated in Fig. 5.44, these dangers may be avoided by cambering the culvert so that after settlement occurs, the culvert grade line will be at or close to that desired. Almost any type of culvert that is not cast in place may be cambered. These include precast concrete pipes and box culverts, corrugated metal pipes, structural-plate steel or aluminum pipes, and plastic pipes. The amount of camber required can be determined by a soils engineer.

5.10.2 Jacking and Tunneling

Should open-trench construction prove uneconomical or the disruption to the traveling public too great, either jacking or tunneling may prove to be more efficient. Either

Cambered Pipe

Cambered Pipe

Camber

Final grade after settlement

FIGURE 5.44 Illustration of camber to allow for settlement of culvert under high fill.

(From Handbook of Steel Drainage and Highway Construction Products, American Iron and

Steel Institute, 1994, with permission)

method removes from consideration the possible disruption of traffic. In addition, for deep fills, these methods can be economically competitive with the open-trench method. The designer should be cautioned that when jacking or tunneling is used, small differences in anticipated geologic conditions may lead to large changes in the method by which the contractor solves the problem. For example, the difference between “running” and “flowing” ground can be not only very costly, but disastrous as well. If unanticipated geologic conditions are encountered by the tunneling or jacking contractor, the cost of the contract could increase dramatically. For this reason, if geologic conditions are in doubt, the designer is advised to obtain adequate geotechnical information through borings.

Jacking. Jacking of underground structures requires that the structure being jacked be able to withstand the large compressive forces acting on it. This generally limits the possibilities to reinforced concrete pipe, reinforced concrete boxes, and solid wall steel pipes. The first step is to adequately provide for a jacking pit, or to design a thrust wall if the jacking is to take place above ground. The jacking force and the adequacy of the structure itself to withstand that force are often left to the contractor. The jacking force required is dependent upon the type and diameter or span of the structure, the type of soil, the amount of overfill, and the jacking distance. Table 5.28 provides values of frictional resistance on reinforced concrete pipe determined from past jacking projects. These values may be reduced if a lubricant such as bentonite slurry is injected into the void created by the overcut. If the frictional resistance is too high for the thrust blocks or the jacks, intermediate jacking stations may be necessary.

|

TABLE 5.28 Frictional Resistance of Reinforced Concrete Pipe for Jacking Projects

|

Soil condition

|

Frictional resistance, lb/ft2

|

Frictional resistance, kN/m2

|

|

Rock

|

040-60

|

02-3

|

|

Firm clay, silt

|

100-400

|

5-20

|

|

Wet sand

|

200-300

|

10-15

|

|

Dry loose sand

|

500-900

|

24-45

|

Source: From S. J. Klein, “Geotechnical Aspects of Pipe Jacking Projects,”

Pipeline Crossing Proceedings, Special Conference, Pipeline Division, American Society of Civil Engineers, Denver, March 25-27, 1991, with permission.

|

Tunneling. Tunneling through soft ground is accomplished by pushing a shield forward and erecting a liner inside of it. The shield is then pushed off the liner as the tunneling progresses, so that there is no limit to the length that may be tunneled. The initial liner may consist of precast concrete sections, steel tunnel liner plates, or steel ribs with either wood or steel lagging. After the liner is erected within the shield and the shield is jacked forward, the void created between the liner and the ground due to overcut may or may not need to be grouted. The grouting of this area depends upon the judgment of the engineer and the type of liner. Tunnel liner plates may not be expanded once they are erected. Because of this, the void caused by the overcut is generally grouted. Precast concrete sections and steel ribs may be expanded to contact the earth once the shield is jacked forward. In this case it is left to the judgment of the engineer whether or not grouting is necessary. After the tunnel is completed, the carrier pipe is placed inside the liner and the void between the two is generally filled with either sand or grout.

Microtunneling. Microtunneling is a term used to describe a method of horizontally boring pipes approximately 36 in (900 mm) in diameter and smaller, using highly sophisticated remotely controlled equipment. The use of lasers allows for extremely accurate placement of the pipe in both grade and alignment. The pipe is jacked from a jacking pit as the tunnel is being bored and the spoils are removed.

Directional Drilling. Directional drilling is similar to microtunneling except that where microtunneling is a one-stage process, the directional drilling method consists of first drilling a pilot hole, reaming it to the proper diameter, and then pulling the pipe through. Because of this methodology, no jacking pit is required. This method has a high degree of precision in location of grade and may be used where the pipe diameter is 42 in (1050 mm) or smaller and the length to be placed is less then 5000 ft (1.5 km).

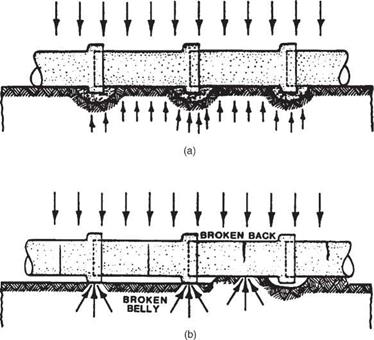

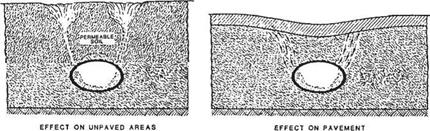

Stabilization Methods for Tunneling. As previously stated, tunneling may be required where it is necessary to keep a roadway or rail line open. This may occur where there is little fill over the crown of the excavation, or where there is adequate fill but it is lacking in stiffness or cohesive strength. When this happens, the soil above the excavation cannot, by itself, develop an arching effect that will adequately support the roadway. This situation necessitates unusual solutions such as chemical grouting, compaction grouting, ground freezing, and the use of spiles. The applicable method of increasing the support depends upon the site and soil conditions. Chemical grouting, compaction grouting, and ground freezing are all methods of stabilizing the soil. Spiles are horizontally drilled small-diameter holes extending from one side of the proposed tunnel to the other and surrounding the tunnel, generally in an arch shape. The holes, after being drilled, have a steel pipe placed in them, which is subsequently filled with concrete. The spile diameter is commensurate with the size of opening to be excavated, and the spacing is reliant upon the amount of coverage and cohesiveness of the soil. After the spiles are in place, the tunnel excavation may begin with steel arch supports placed as necessary.

Welded wire

Welded wire

Cambered Pipe

Cambered Pipe