Terrain Effects

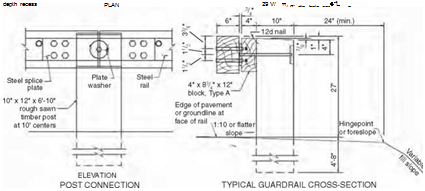

Ideally, at the moment of impact, a vehicle should have all wheels on the ground and the suspension system in a neutral state. Thus, terrain conditions between the traveled way and the barrier are very important. For example, curbs should be avoided and should be no higher than 4 in (100 mm) if used. In many cases, they can be located behind the barrier. Barriers are usually tested on level terrain. If installed on slopes steeper than 1:10, vehicles may go over standard barriers or impact them too low, and thus not perform as anticipated.

Roadside barriers must be flared (must have variable offset from the traveled way) to locate the barrier terminal back from the roadway and thus to minimize drivers’ reaction to a perceived hazard near the road when approaching a bridge parapet or railing, for example. However, the greater the flare rate, the greater the potential impact angle and the severity of an accident if the barrier is hit. Also, the chance that a vehicle would be redirected across the roadway increases. Maximum flare rates depend on design speed, barrier type, and location relative to the shy line as shown in Table 6.4. Adjustment to a flatter rate is sometimes made to avoid extensive grading.

Flare rate for

barrier beyond shy line

|

70 (110) |

30:1 |

20:1 |

15:1 |

|

60 (100) |

26:1 |

18:1 |

14:1 |

|

55 (90) |

24:1 |

16:1 |

12:1 |

|

50 (80) |

21:1 |

14:1 |

11:1 |

|

45 (70) |

18:1 |

12:1 |

10:1 |

|

40 (60) |

16:1 |

10:1 |

8:1 |

|

30 (50) |

13:1 |

8:1 |

7:1 |

|

Design speed, Flare rate for barrier Rigid Semirigid mi/h (km/h) inside shy line systems systems |

|

Source: From Roadside Design Guide, AASHTO, Washington, D. C., 2002 and 2006, with permission. |

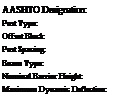

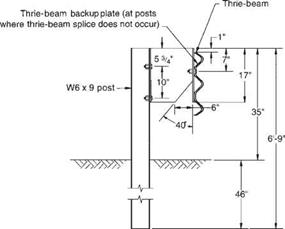

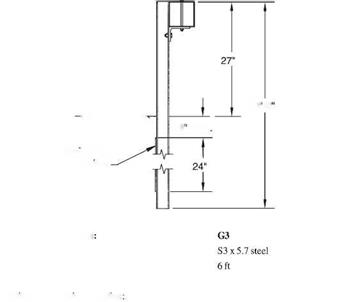

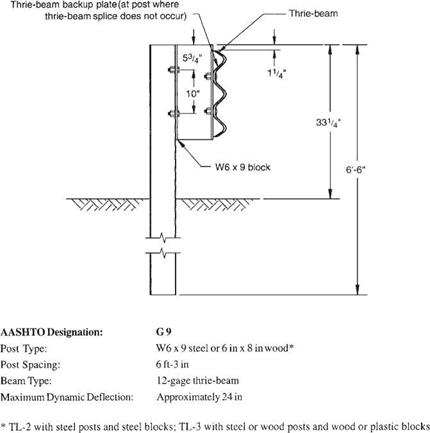

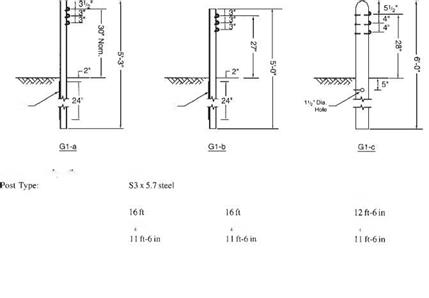

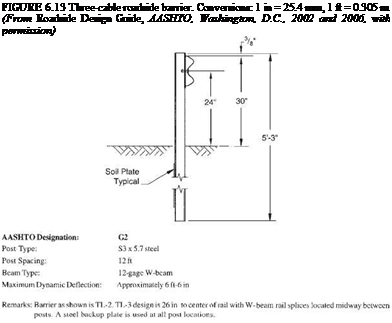

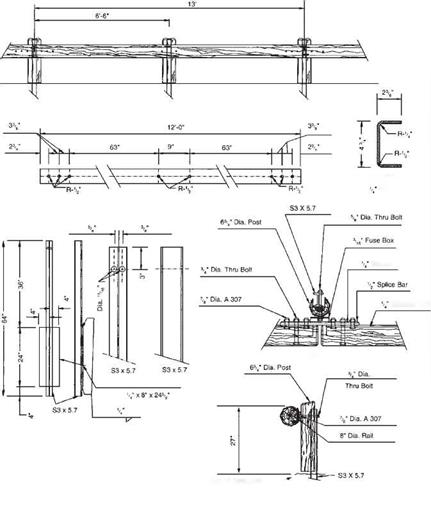

Post Type: Post Spacing:

Post Type: Post Spacing:

system meets Tl-2 or TL-3, depending upon details. The system is sensitive to mounting height and irregularities in terrain.

system meets Tl-2 or TL-3, depending upon details. The system is sensitive to mounting height and irregularities in terrain. Shielding generally required A judgment decision based on nature of fixed object and likelihood of impact A judgment decision based on size, shape, and location of obstacle Shielding not generally required A judgment decision based on likelihood of impact

Shielding generally required A judgment decision based on nature of fixed object and likelihood of impact A judgment decision based on size, shape, and location of obstacle Shielding not generally required A judgment decision based on likelihood of impact FIGURE 6.12 (Continued)

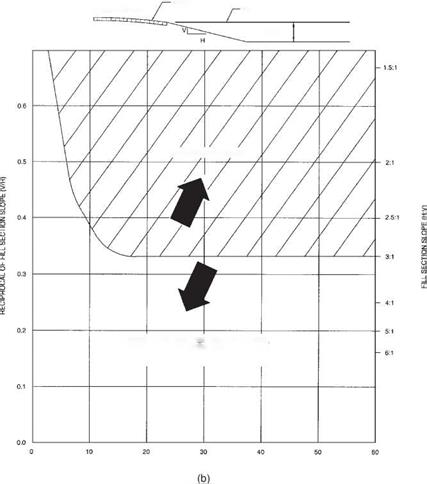

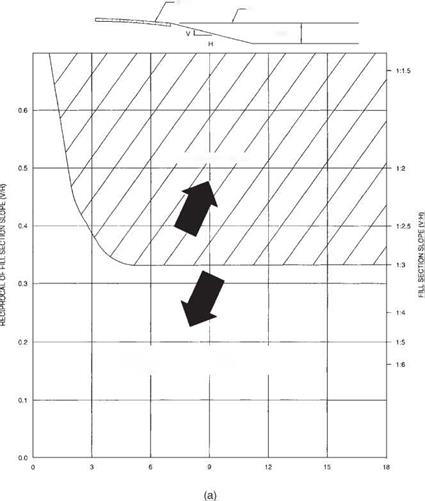

FIGURE 6.12 (Continued) FILL SECTION HEIGHT (m)

FILL SECTION HEIGHT (m)