In some parts of the country, carpenters raise the walls before cutting and nailing on the double top plate. In my opinion, the time to nail on the double top plate is now—while the wall is still flat on the floor. Otherwise, you will have to use a ladder. The top plate is an important structural member. It ties the entire frame together. Without it, severe lateral stress from an

earthquake or high winds could easily rip apart a building. If you frame with a single top plate, secure them together with metal plate straps.

On a 2×4 butt wall, the double top plate extends beyond the top plate a bit less than ЗУ2 in. (cut it /4 in. short—about 3/4 in.—to make sure it doesn’t protrude beyond the through wall), so that it can tie into the notch in the double top plate of a through wall. On through walls, the double top plate has notches where it receives the double top plates extending from butt or intersecting walls. Now you can see why it was important to mark the plates accurately while locating the corners and channels. You don’t need to measure the length of double top plates. All you need to do is set the double top plate on a through wall above the top plate, with one end held back З’А in. (5У2 in. on 2×6 walls) from the end, then cut it to length.

At channel marks, leave a 33/4-in. cutout so that an intersecting wall can comfortably lap over and tie in at that spot (see the photo on p. 100). When cutting and installing double top plates, leave about a 3/4-in. gap where the walls

tie into each other. This makes it easier for the overlapping double top plates to slip into place. This is another one of those times when it’s okay to be less than absolutely accurate.

When you nail the double top plate to the top plate, it’s important to make sure that there are no gaps in the top plate. The top plate stock must butt tightly together, just as it did when you plated the walls on the subfloor. Nail the double top plate to the top plate with two 16d nails at each end of the wall and at each break in either the top plate or the double top plate. Elsewhere, nail one 16d nail over each stud.

It is best not to nail between studs, because electricians and plumbers run wires and pipes through holes drilled in those locations. Hitting a nail while drilling can dull the bit and give your arm a nasty twist.

Brace the walls

The sudden, intense pressure exerted on a wall by a hurricane, tornado, or earthquake can be devastating. To withstand these forces, the walls must be well braced. As a novice carpenter, I

used to cut 2x stock with a handsaw and nail them between the studs, running it diagonally from plate to plate. It was a good brace, but it took about an hour to make each one. These days, braces are much easier to install. You can attach L-shaped metal angle braces or nail plywood or OSB sheathing to the frame. Code requirements vary, so be sure to check with your building department to find out how the walls should be braced. In some areas, bracing is also required on certain interior walls.

used to cut 2x stock with a handsaw and nail them between the studs, running it diagonally from plate to plate. It was a good brace, but it took about an hour to make each one. These days, braces are much easier to install. You can attach L-shaped metal angle braces or nail plywood or OSB sheathing to the frame. Code requirements vary, so be sure to check with your building department to find out how the walls should be braced. In some areas, bracing is also required on certain interior walls.

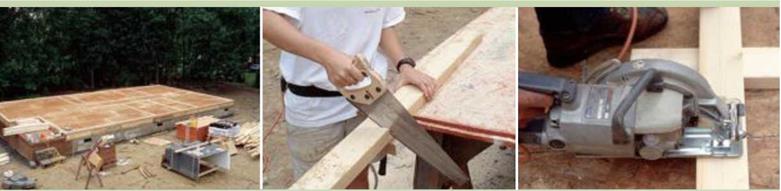

USING METAL ANGLE BRACES. Metal angle braces are easy to install (see the photos on the facing page). In many areas, they can be used instead of plywood or OSB sheathing.

If the finished siding you plan to install can be nailed directly to the studs or furring strips (clapboards and fiber-cement boards are good examples), metal braces can save you the

expense of plywood or OSB sheathing. Every exterior wall should receive a metal brace at every corner as well as every 25 ft. between corners. The typical metal brace has an L – shaped profile; it’s designed to be set into a kerf cut diagonally across the wall. Here’s how to install one:

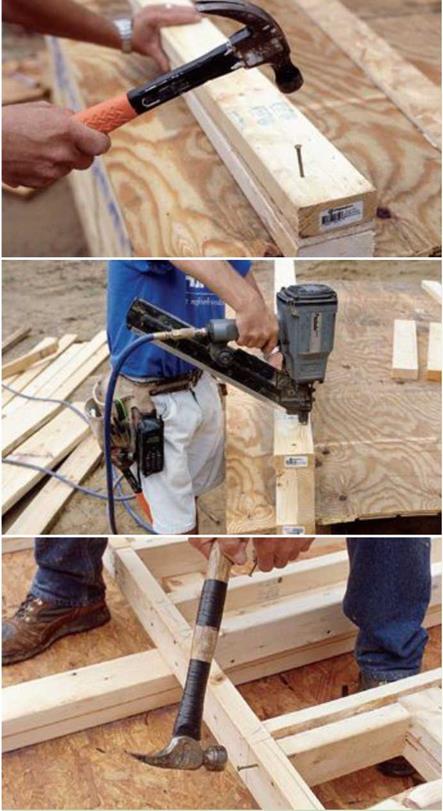

1. Position the brace and mark the cut. Lay

the brace across a framed wall so that it extends at a 45-degree angle from the bottom plate to the double top plate. Trace a pencil mark along one side, as shown in the far left photo on the facing page.

2. Cut the kerf. With a circular saw, cut a l-in.-deep slot along the line into the plates and studs.

3. Nail off the bottom of the brace. Slip one

flange of the brace into the slot and nail it to the bottom plate with three 8d nails. Drive one more 8d nail through the brace and into the first stud. At the double top plate, start an 8d nail alongside the brace and bend the nail over to hold the brace in place as the wall is raised.

Now you are ready to raise and plumb the wall. It’s important not to install the brace completely until after the wall has been raised and plumbed. See pp. 101—108 for details on raising and plumbing walls.

Finish nailing the brace to the studs and plates by driving one 8d nail through the brace and into every stud it crosses. At the top of the wall, drive three nails through the brace and into the top and double top plates. If the top of the brace extends above the double top plate, trim it flush with a hacksaw.

USING PLYWOOD AND OSB BRACING. When nailed properly to wall framing, plywood and OSB provide much stronger racking resistance than metal braces do. Wall sheathing is essential as a substrate for some types of exterior siding. It also acts as a wind and weather barrier. Many codes require that a full sheet of OSB be nailed at each exterior corner and every 25 ft.

along the wall. The spaces between can be filled with sheets of rigid foam insulation. That’s the sheathing strategy we used on this house.

There are different ways to install wood sheathing panels. Sometimes sheathing is positioned to extend over the wall and cover the rim joist. I try to keep OSB V2 in. away from concrete so it won’t absorb water. On a one-story building, my preference is to sheathe the walls once they are raised. This is especially true when working on a slab that has plumbing pipes sticking up.

Other builders prefer to sheathe the walls while they are flat on the floor. One of the problems with sheathing the walls before raising them is that they become heavy. To raise a long 2×6 wall fully sheathed with OSB or plywood, you may have to call in the National Guard.

Or you could use a wall jack, a device that hooks under a wall and slowly raises it up (see

Resources on p. 279). Sheathing a wall while it’s still flat on the subfloor also requires greater accuracy—the wall must be dead-on straight and square before it’s sheathed. You can do this by making sure the bottom plate is directly on the chalkline and the end corner studs are flush with the outside of the building. It doesn’t hurt to measure from corner to corner to check the wall for square. After the wall is ready, you can attach the required sheets of plywood or OSB (8d nails every 6 in. o. c. around the perimeter,

12 in. o. c. in the field, or middle of the sheet). Be sure to insulate headers, corners, and channels before covering them with sheathing.

When the last wall has been raised, something special happens. What was once just a jumble of framing lumber on the deck all of a sudden feels like a house with real rooms.

When the last wall has been raised, something special happens. What was once just a jumble of framing lumber on the deck all of a sudden feels like a house with real rooms. Raise interior walls from the longest to the shortest

Raise interior walls from the longest to the shortest

the wall is in position, nail through the bottom plate and into the subfloor, using one 16d nail between each stud. Be sure to drive a 16d nail close to each king stud. Drive plate nails into the rim joist or into a floor joist. Nails driven through the subfloor alone don’t have nearly as much holding power as those embedded in framing lumber. Don’t nail in doorways, because you’ll be cutting out the plate later when you set the door frame.

the wall is in position, nail through the bottom plate and into the subfloor, using one 16d nail between each stud. Be sure to drive a 16d nail close to each king stud. Drive plate nails into the rim joist or into a floor joist. Nails driven through the subfloor alone don’t have nearly as much holding power as those embedded in framing lumber. Don’t nail in doorways, because you’ll be cutting out the plate later when you set the door frame.

![STEP 6 RAISE THE WALLS Подпись: 1. To mark the cut line, position the brace diagonally across the wall section from the bottom plate to the double top plate, and then pencil a line along one edge of every framing member the brace crosses. [Photo © Larry Haun]](/img/1312/image329_0.gif)

![STEP 6 RAISE THE WALLS Подпись: The first wall goes up! Make sure you have enough help when you're ready to raise the walls. Have one person take charge, and get everyone to lift in unison. [Photo by HFHI/Will Crocker]](/img/1312/image331_0.gif) When you remove the temporary blocks nailed to the rim joist, be sure to pull the nails or bend them over so that no one gets a nail in the foot!

When you remove the temporary blocks nailed to the rim joist, be sure to pull the nails or bend them over so that no one gets a nail in the foot!

used to cut 2x stock with a handsaw and nail them between the studs, running it diagonally from plate to plate. It was a good brace, but it took about an hour to make each one. These days, braces are much easier to install. You can attach L-shaped metal angle braces or nail plywood or OSB sheathing to the frame. Code requirements vary, so be sure to check with your building department to find out how the walls should be braced. In some areas, bracing is also required on certain interior walls.

used to cut 2x stock with a handsaw and nail them between the studs, running it diagonally from plate to plate. It was a good brace, but it took about an hour to make each one. These days, braces are much easier to install. You can attach L-shaped metal angle braces or nail plywood or OSB sheathing to the frame. Code requirements vary, so be sure to check with your building department to find out how the walls should be braced. In some areas, bracing is also required on certain interior walls.

![NAILING TOGETHER THE WINDOW FRAME ASSEMBLIES Подпись: Door and window assemblies are nailed together and ready to be installed between the top and bottom wall plates. [Photo © Larry Haun]](/img/1312/image312.gif) the ground, add lots of compost, plant good seeds, mulch well, and nurture young plants, you can’t help but grow outstanding vegetables. The situation is similar when you’re framing walls. If you take the time to lay out, cut, and correctly position every part of every wall, then the actual framing will go smoothly and you’ll produce a quality building.

the ground, add lots of compost, plant good seeds, mulch well, and nurture young plants, you can’t help but grow outstanding vegetables. The situation is similar when you’re framing walls. If you take the time to lay out, cut, and correctly position every part of every wall, then the actual framing will go smoothly and you’ll produce a quality building.

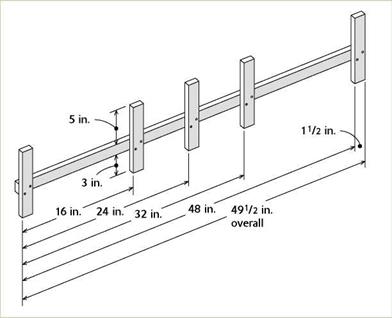

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

Start the stud layout at one end of a long exterior wall. Place the layout stick on the outside edge of the plates, with the first tab 3/4 in. beyond the end of the wall. This sets up a 16-in.- o. c. or a 24-in.-o. c. layout that will accommodate the 4-ft.-wide sheathing sheets (see the photo above). Mark both sides of the remaining tabs to note the locations of the next three studs. Move the layout stick, line up the end tab with the last mark, and mark again. If you’re nailing a sheet of OSB at the outside corners for bracing, make sure you lay out a stud 4 ft. from each corner in both directions.

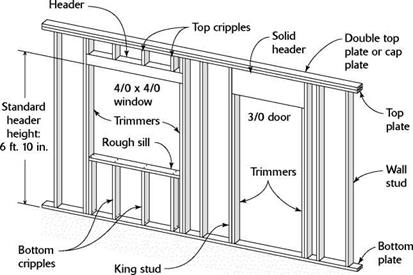

STUDS are spaced on 16-in. or 24-in. centers. The length of the stud determines the overall height of the wall. Standard stud length is 92% in.

STUDS are spaced on 16-in. or 24-in. centers. The length of the stud determines the overall height of the wall. Standard stud length is 92% in.