Each day, a mature living tree can pump a ton of water into the atmosphere, so it’s no surprise that logs arrive at the mill with moisture contents of 30 percent to 55 percent. Consequently, a sawmill will rough-cut logs into lumber, air dry or kiln dry it, and then grade the lumber’s moisture content before planing (surfacing) it.

Moisture content of 15 percent to 19 percent is optimal because that approximates the moisture content of ambient air in much of North America, except in the dry U. S. Southwest. Most often, lumber will be marked S-DRY or KD (kiln dried), indicating that its moisture content is 19 percent or less. KD-15 or MC-15 indicates a moisture content of 15 percent or less. Of course, even MC-15 lumber may be sopping wet if rained on during storage or transport. Wood that’s drier than MC-15 (say, 7 percent to 8 percent MC) may be a problem because it could swell after absorbing moisture on the job site—unless you live in the Southwest.

Softwoods

Softwoods

Most construction lumber is called softwood, which is the lumber industry’s term for wood from conifers, the needle-leaved evergreens such as pine, fir, spruce, and hemlock. For the most part, these softwoods are softer and less dense than most hardwoods, which come from broad-leaved deciduous trees such as maple, oak, and walnut. That said, some softwoods, namely southern yellow pine, are much harder

A grade mark of S-GRN (surfaced green) indicates a moisture content more than 19 percent. Green lumber is hell to work with because it’s heavy (a green 8-ft.-long 2×4 can weigh 40 lb.), likely to distort, and certain to shrink—wreaking havoc with finish surfaces and trim. Thus S-GRN is a risky choice for renovations.

LUMBER SIZES

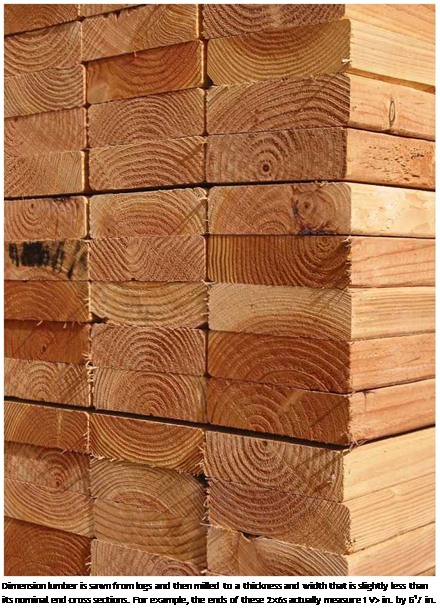

Lumber’s final size depends on milling processes. In smaller mills, lumber is often sawn, stickered, and allowed to air dry for 4 months to 6 months. If it’s not milled further, it’s called rough-cut lumber. Depending on the accuracy of the sawyer, the size may vary slightly, but the nominal size of, say, a rough-cut 2×4 is usually a full 2 in. by 4 in.

However, most lumber is rough cut and then surfaced (run through a planer to achieve uniform thickness) before being kiln dried. At each stage, the lumber size decreases. Thus when you order a 2×4 (nominal size), you receive a piece with a 112-in. by 312-in. cross section (actualsize). Still, you pay for the nominal size.

Another way to size wood, especially hardwood and Select finished woods, is by quarter – inch increments: 2/4, 3/4, 4/4, 5/4,6/4, and so on. The nominal actual difference is present here, too: For example, a nominal 5/4 stair tread is actually 1 in. thick.

PRESSURE-TREATED LUMBER

Lumber may also be marked as pressure treated. Such wood, after treatment, may be left exposed to weather, used near the foundation, or otherwise subjected to moisture, insects, or extremes of climate. If the wood will remain in contact with the soil, be sure that it is also rated for Ground Contact.

Since the 1940s, roughly 90 percent of all pressure-treated lumber was treated with CCA

(chromated copper arsenate). But the U. S. Environmental Protection Agency (EPA) determined that CCA leaches arsenic into the soil; as a result, industry leaders agreed to stop using that treatment by the end of 2003. More benign types of pressure-treated lumber, such as.40 ACQ (alkaline copper quat) and CBA (copper boron azole) are available. Both biocides are arsenic free.

Whatever lumber treatment you consider, consult its product data sheets for the relative safety of the chemicals used and whatever care you should take when handling, storing, cutting, and applying it. In fact, it’s smart to capture and safely dispose of the sawdust.

ORDERING LUMBER AND CALCULATING BOARD FEET

The price of long thin pieces of wood, such as molding or furring strips, is based on their length, or lineal feet (lin. ft.). Sheet materials such as plywood and composite board are sold by the square foot, which is length times width; sheet thickness affects price, but it is not computed directly. Roofing and siding materials are often sold in squares of 100 sq. ft. Most yard lumber is sold by board feet, according to this formula:

width (in.) x thickness (in.) x length (ft.)

12

12

|

Nominal and Actual Sizes of Softwood

|

|

NOMINAL

|

ACTUAL (in.)

|

|

1×2

|

3/4x1V2

|

|

1×4

|

3/4x3V2

|

|

1×6

|

3/4×51/2

|

|

1×8

|

3/4×71/4

|

|

1×10

|

3/4×91/4

|

|

1×12

|

3/4×111/4

|

|

2×4

|

11/2×31/2

|

|

2×6

|

11/2×51/2

|

|

2×8

|

11/2×71/2

|

|

2×10

|

11/2×91/2

|

|

2×12

|

11/2×111/2

|

In the two examples below, each board contains 1 board foot (bd. ft.):

In the two examples below, each board contains 1 board foot (bd. ft.):

12 in. x 1 in. x 1 ft.

= 1 bd. ft.

12

6 in. x 2 in. x 1 ft.

= 1 bd. ft.

12

In each of the following two examples, the dimensions given yield 2 bd. ft.:

12 in. x 1 in. x 2 ft.

= 2 bd. ft.

12

2 in. x 4 in. x 3 ft.

————————— = 2 bd. ft.

12

When calculating the total board feet of several pieces of lumber, multiply the numerator (top part) of the fraction by the total number of pieces needed. Thus here’s how to calculate the board feet of 10 pieces of 2-in. by 6-in. by 12-ft. lumber:

2 in. x 6 in. x 12 ft. x 10

= 120 bd. ft.

12

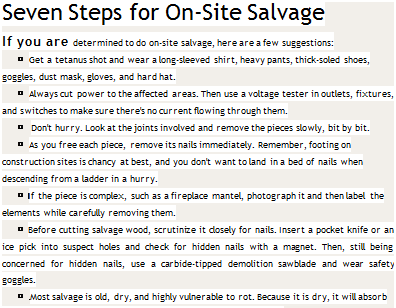

Salvage Lumber

Salvage materials have striking advantages and disadvantages—the major plus being low cost; the major minus being prep time. Salvaging molding, flooring, and other materials from your own home is a good way to match existing mate

rials, but be picky in selecting materials from other sources.

Reuse centers are popular these days. One example is Habitat for Humanity’s nonprofit stores, which offer tax deductions to donors and savings up to 75 percent off the original price of materials.

However, make sure all materials are structurally sound. Be sure to use a pocketknife to test lumber for rot or insects. Also treat with preservative any salvaged lumber that you’ll use as sills or that will be exposed to moisture.

Salvage materials usually aren’t worth the effort if they are in small quantities or if, after removing them, you find that they will be too short. Used 2x4s, for example, normally aren’t worth the trouble. By the time you yank them free from plates, remove nails, and cut off split ends, the studs may be only 7 ft. long.

Some materials just aren’t worth removing. For example, siding and other exterior trim is rarely worth saving, for it’s usually old and weather beaten. Barn board, in vogue years ago, is hardly charming when it is half-rotted, warped, and crawling with carpenter ants. If there is any danger of your destroying a piece of salvage by removing it, leave it alone. Parts of many beautiful old places that were restorable have been ruined by people who didn’t know what they were doing.

If you have any qualms about the structural strength of a building, stay out of it. Dismantling a building is a special skill, and inexperienced people who undertake the task can get hurt. Perhaps the best advice for would-be users of salvage materials is to buy it from a salvage yard. In this case, somebody has already done the dirty and dangerous work of removal.

12

12 In the two examples below, each board contains 1 board foot (bd. ft.):

In the two examples below, each board contains 1 board foot (bd. ft.):

strength, appearance, or both. The more imperfections, the lower the grade.

strength, appearance, or both. The more imperfections, the lower the grade.

for framing, roofing, and shingling, and you can begin to imagine the number of hammer strokes required. Pneumatic nailers, commonly called nail guns, can reduce those strokes to a small fraction.

for framing, roofing, and shingling, and you can begin to imagine the number of hammer strokes required. Pneumatic nailers, commonly called nail guns, can reduce those strokes to a small fraction.

ends for better leverage. The longer the bar, the better the leverage.

ends for better leverage. The longer the bar, the better the leverage.

Block planes shave off tiny amounts of wood from door edges, casings, and other thin stock, allowing tight, final fits of materials.

Block planes shave off tiny amounts of wood from door edges, casings, and other thin stock, allowing tight, final fits of materials.

Bullnose planes can fine-shave wood edges in tight places. Bullnose blades are the same width as plane shoes. You can remove the bullnose front piece, allowing you to plane right up to the juncture of an adjoining piece.

Bullnose planes can fine-shave wood edges in tight places. Bullnose blades are the same width as plane shoes. You can remove the bullnose front piece, allowing you to plane right up to the juncture of an adjoining piece.