Skylight above a Flat Ceiling

Positioning a skylight above a flat ceiling is an inexact science. Situating the skylight between rafters is easy enough, but because lightwells flare out, sizing and positioning the ceiling opening can be tricky if you’ve never done it before. Here are a few tips to demystify and simplify the process.

► Use a pencil or painter’s tape to roughly outline the lightwell opening on the ceiling. Push nails up through the corners of the opening so you can spot them from above.

► Go into the attic or crawl space above to find the four corner nails and determine if there are wires, pipes, and ducts that would be a problem to relocate. Avoid positioning skylights where roof planes converge, by all means. It’s far easier to reposition the skylight.

► If the space over the ceiling is inaccessible, turn off the electricity and use

a cordless recip saw (or a hammer) to punch a hole big enough for your head, so you can take a better look before enlarging the hole.

► If you can position skylight openings to avoid cutting rafters or ceiling joists, do so. If you must cut more than one rafter, have an engineer review your plans. Otherwise, double up headers and trimmers around the rough opening(s) to redistribute the loads, and use steel connectors to ensure solid connections.

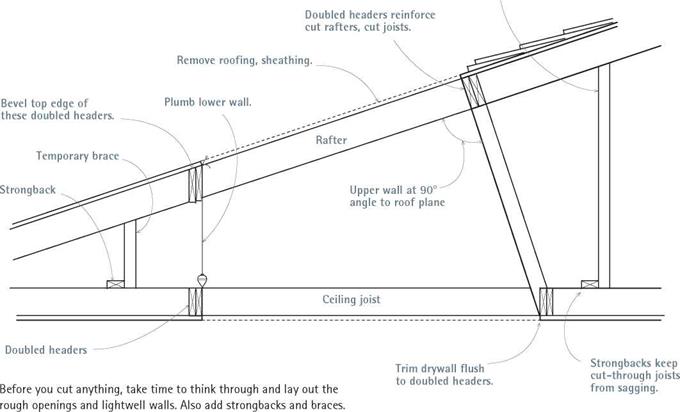

► Flare the top and bottom of the lightwell but, if possible, leave the sides vertical. To simplify layout further, make the upper (end) wall of the lightwell perpendicular to the rafters and the lower (end) wall, plumb, as shown in "Skylight Positioning," at left. It’s possible to flare all four surfaces, but compound-angle cuts on all studs are a monster to do correctly.

► When you have a better sense of the lightwell’s location, enlarge the hole

in the ceiling but don’t cut it to its final size yet. To mark the corners of the opening in the roof, drive 16d nails up through the sheathing. Note: Thus far you’ve cut into finish surfaces only, not into framing.

|

|

|

|||

|

|

||

shingles within the RO without disturbing those around the perimeter.

Once you’ve removed the shingles within the RO, use a circular saw with demolition blade set to the depth of the roof sheathing. If you’re skilled, you can use a reciprocating saw with a bimetal blade to cut through the sheathing, as the pro is doing in the photo on p. 121, but don’t cut through a rafter while you’re standing on it! Whatever tool you use, wear eye protection because you’re likely to hit nails. After you’ve cut around the perimeter of the RO, use a claw hammer or a flat bar to pry out the sheathing.

Next slide a shingle ripper under the shingles around the RO, gently breaking the self-sealing shingle spots and pulling out any nails within 1 ft. of the opening. This nail-free perimeter will enable you to properly flash the skylight curb with building paper or self-adhering bituminous flashing. Finally, if you’re installing a skylight with L-shape mounting brackets, cut back the shingles an additional 1 h in. to 2 in. around the RO so the brackets can sit on a uniformly flat surface and be screwed easily into sheathing.

Framing. Frame the roof opening and the light – well. Before cutting through the rafters, install temporary braces to the ceiling joists below; those rafter braces stay in place till the rafters are head – ered off. If the upper wall of the lightwell will be perpendicular to the rafters, use a framing square to mark a square cut back 3 in. from the edge of the opening (a doubled header is 3 in. wide).

The lower end of the lightwell is a bit trickier to frame because it intersects the roof plane at an obtuse angle (greater than 90°). Hold a 4-ft. level plumb against the lower edge of the roof RO, and then mark that angle onto the face of the trimmer rafters on each side of the opening. Bevel-cut the top edges of the doubled headers at that same angle. Once you’ve headered off the top and bottom of the RO, double up the trimmer rafters along the sides of the opening, using as long a board as possible. (Space is tight in an attic.)

Finally, install studs running from the RO in the roof to the RO in the ceiling below. If you install the four corner studs first, you can run taut strings between them to align the intervening studs. If the lightwell sidewalls are plumb, rather than flared out, you will have saved yourself a lot of work.

1111

1111

Replace and renail the siding, as necessary; then caulk and install the window as described in the next section.

Replace and renail the siding, as necessary; then caulk and install the window as described in the next section.

Hanging the Door

Hanging the Door