WEATHERSTRIPPING JAMBS

Today, there are three main types of weatherstripping: tubular, metal-leaf, and kerf-in. Most are easy to install and require few special tools. Prehung doors usually come with weatherstripping attached, which can be a nuisance when installing the unit and trying to establish a uniform gap between the door and its jamb all around. Thus many installers remove kerf-in weatherstripping before beginning the installation; it’s easy enough to slide the strips back into the kerfs when the job is done. Door shoe gaskets (which seal the bottom of a door) are removed for the same reason.

Tubular is the easiest to install on old doors and the least expensive type of permanent weatherstripping. The reinforced part of the strips is usually metal, with slots for attaching screws; slots allow you to adjust the stripping so it fits tight to windows or doors. To install tubular weatherstripping, shut the door and press the strip’s flexible seal against the door, then screw the reinforced part to the jamb; if it’s metal, use a hacksaw or aviation snips to cut it. Don’t buy tubular stripping that nails up or has round holes (not slots), because it can’t be adjusted.

Metal-leaf, commonly called a V-bronze or metal-tension strip, is a thin metal strip folded lengthwise and nailed with brads to door jambs. When the door shuts, it compresses the metal, stopping drafts. Metal tension strips are durable

|

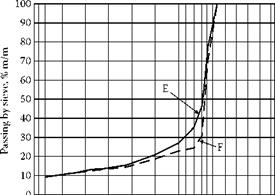

Kerf-in weatherstripping is essentially the same for doors and casement windows. Both compress the flexible stripping as they shut, sealing out drafts and moisture. |

|

|

|

and, because they fit between the door or window and its frame, are hidden when the door is shut. When installing it, place the leaves flush to the doorstop, spacing brads every 3 in. Install the head piece first, then the sides. To keep the leaves from snagging where they meet in the corners, snip them back at a slight angle (5°). In time, the leaves flatten, but they can be raised by running a flathead screwdriver down the center of the fold.

Kerf-in features flexible stripping (silicone, vinyl, foam) that slides into a kerf (slot) between the jamb and the doorstop. Kerf-in is the preferred weatherstripping for new prehung doors because it seals tightly and can be easily replaced if the

stripping gets worn out. To cut kerfs into existing frames, use a kerfing tool, which looks like a laminate trimmer on an angled base. Silicone stripping is a good choice for retrofits because it compresses so small that old doors shut easily without doorstop adjustments. At head-jamb corners, cut stripping at 45° angles so it lies flat.

Exterior doors should have a dead bolt with a minimum 1-in. throw (extension) and a reinforced strike plate that screws into the framing behind the door frame. Single-cylinder deadbolts have a thumb-turn on the interior that is easy to open in the event of a fire. Unfortunately, such thumb-turns can easily be turned by a burglar breaking a glass side light. Double-cylinder models, which require a key on both sides, are more secure but are frequently banned by fire codes.

Exterior doors should have a dead bolt with a minimum 1-in. throw (extension) and a reinforced strike plate that screws into the framing behind the door frame. Single-cylinder deadbolts have a thumb-turn on the interior that is easy to open in the event of a fire. Unfortunately, such thumb-turns can easily be turned by a burglar breaking a glass side light. Double-cylinder models, which require a key on both sides, are more secure but are frequently banned by fire codes.

0

0

![Techniques CARRYING LUMBER Подпись: 6]/4 in. (top cripple length) Make a story pole from a 2x s:ud. This pole will help you accurately lay out trimmers, headers, rough sills, and top and bottom cripples.](/img/1312/image313.gif)

Select straight plates. Check 2x plate lumber for bow and twist and select only the straightest boards for plates. This makes for strong, straight walls.

Select straight plates. Check 2x plate lumber for bow and twist and select only the straightest boards for plates. This makes for strong, straight walls.