SEALING DOOR BOTTOMS

Weatherstripping beneath exterior doors must be weather tight and durable, this because of the heavy traffic it must bear in normal use.

Elements that attach to door bottoms are called shoes or sweeps; those that attach to the floor,

|

|

|

|

thresholds. If the doorway is protected by an overhang, installing a shoe/threshold combination will significantly cut drafts under the door. However, if the doorway is exposed or there are signs of water damage around an existing threshold, cover it with the water-return threshold shown on p. 111. Also see "Floor Pan for Exterior Door,” on p. 97.

Attaching sweeps and shoes is straightforward. The simplest are flap sweeps that are nailed or screwed to the bottom of a door while it’s shut. On an outswinging door, cut the sweep to length and hold it against the bottom edge of the door so the sweep touches the threshold. Flap sweeps are not terribly durable, but they’re cheap and easy to install.

Installing shoes is somewhat more complicated because most types cover the bottom edge of the door and have a vinyl seal. Moreover, you need enough space between the door and the threshold to accommodate the thickness of the shoe and its seal (usually Z in., but check manufacturer’s specs). If not, plane or cut down the door.

If there is enough space under the door, pull its hinge pins, and lift the door out. Then, using a hacksaw, cut the shoe to length (12 in. shorter at each end than the width of the door). Shoes have screw slots that let you adjust their height; attach the shoe with one screw at each end. Rehang the door, lower the shoe till its seal makes solid contact with the existing threshold, tighten the screws at that height, and then open and shut the door. The door should drag slightly as you operate it, and you shouldn’t see daylight under the shut door. When you’re satisfied with the shoe positioning, insert and tighten the rest of the screws in their slots.

Retrofitting a water-return threshold is a bit

more work. A three-piece threshold can be installed over an existing threshold. Consisting of a sill cover, a drain pan, and a threshold with weep holes, the assembly is sloped to send water back outside; hence the name water return.

The retrofit requires accurate measurements and careful cutting so all three pieces fit snugly to the existing door frame. To start, measure the widest point of the doorway opening and rough cut the sill cover to that length; then hold one end of the sill cover square to the base of a jamb and scribe the jamb’s profile onto the metal sill. Use a small circular saw with a metal-cutting blade to cut the first end before scribing and cutting the other end. The sill cover must slope about 18 in. toward the outside so it will shed water. Hold a torpedo level on the sill cover while you temporarily shim its back edge up.

Measure and cut the threshold (not the drain pan) next. Usually, the threshold lines up to the outside edge of the doorstop, so when the door shuts, it fits snug to the threshold, as well. As you did with the sill cover, scribe the profile of the jambs onto both ends and cut them out. With the threshold resting on the sill cover, lightly scribe the outside edge of the threshold onto the sill cover, using an awl or a pocketknife. The outer edge of the drain pan should sit just shy of this scribed line. Remove the threshold and scribe the profiles of the jambs onto the drain pan; use aviation snips to cut the pan—it’s very thin.

With all three threshold pieces in place (and sloping toward the outside), measure up 12 in. onto each jamb and make pencil marks. The Z in. indicates the thickness of the door shoe you’ll attach to the bottom of the door. Remove the

(continued on p. 112)

|

|

|

|||

Hinged doors, general

Door binds against top of latch jamb or scrapes floor

Hinge-screw holes in jambs are stripped

Door binds along latch jamb, but hinges are tight

Door binds on latch jamb; hinges are tight; big gap seen along hinge jamb

Door binds along hinge jamb

Door binds because door frame is racked (out of square)

Door shuts but won’t latch

Pocket doors

Door slides roughly

Door slides roughly; floor abraded under door

Door does not slide at all; hard to operate

Door drags, balking at certain points; wheels squeal

Door face abraded; door difficult to operate

Exterior doors

Drafts around door

Water damage to wood doorsill, finish floors, and subfloor

Water stains on interior walls, especially around top of door

Heavy condensation on metal sliding door; floor is water damaged

Door frame not square; casing tilts; large diagonal cracks at corners of doors or windows

Rescrew hinge to jamb, replacing inner screws with ones long enough to reach studs, if needed

Use longer screws or fill holes with white glue, insert toothpicks, allow to dry, and rescrew

Use adjustable wrench to bend hinge-leaf knuckles on door

Remove hinges, chisel hinge gains (recesses) deeper, and reattach hinges

Remove hinges, place cardboard shims under hinges, and reattach

Scribe and trim door to fit skewed opening or replace old frame with squared, prehung door unit

Raise or lower strike plate

Vacuum track thoroughly

Remove trim to expose top-hung mechanism; adjust to raise door

If bottom track, lift door back onto it; if top track, remove trim and set tracking wheels up onto track

Remove trim, swing door out, and oil or replace wheels; use flashlight to examine track inside pocket

Lift door onto track; if problem persists, remove finish wall on one side-may need to replace stud

Install weatherstripping or new threshold

Replaced damaged materials; install water-return threshold to keep water from getting in

Remove siding above top of door frame and retrofit cap flashing

Upgrade to vinyl-clad door with better insulating properties

Have structural engineer check foundation

PRO"ГIP

Metal thresholds are thin enough to cut with hacksaws or jigsaws. But a small (33/s-in.) cordless circular-saw blade is wide enough to track properly and cut square, yet agile enough to notch door-frame profiles. Play it safe: Don’t hand-hold stock while cutting it. Clamp it down so your hands are free. And by all means, wear eye protection and work gloves when cutting metal.

1111

PRO TIP

If hinges are loose because the screw holes are stripped, fill the holes with epoxy putty. Allow that to harden before predrilling and replacing the screws. Don’t bother filling holes with standard wood putty, since it won’t hold.

1111

Select the right chalk.

Select the right chalk.

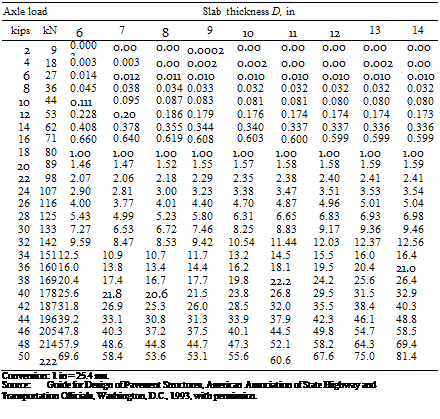

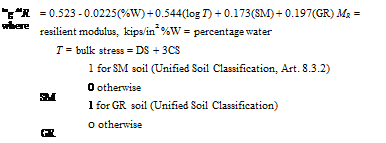

resilient modulus, kips/in2 plasticity index percentage water

resilient modulus, kips/in2 plasticity index percentage water

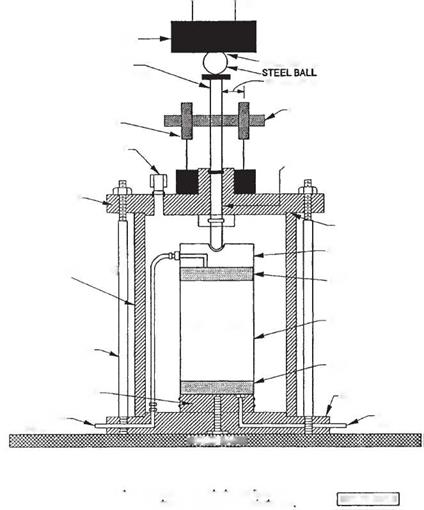

REPEATED LOAD ACTUATOR

REPEATED LOAD ACTUATOR Note: LVDT tips shall rest on the triaxial cell itself or on a

Note: LVDT tips shall rest on the triaxial cell itself or on a