Objectives. The purpose of this phase is to select the most promising alternatives from among those generated during the previous phase. During the creativity phase there is a conscious effort to prohibit any judicial thinking so as not to inhibit the creative process. But in the evaluation phase, all the alternatives must be critically evaluated because many of them may not be feasible. The alternatives are studied individually and/or grouped for the best solution. Identifying function may seem like a simple process—so simple, in fact, that it seems only a “simple” mind would be required to get the job done. In some ways this is true; a mind that can work in a simple, direct way is required—a mind with the ability to reduce concepts, ideas, and analyses to their best common denominators. The emphasis on function in this phase is what makes the VE approach radically different from any other cost reduction effort.

Key Questions. The following questions must be answered about all alternatives being developed during this phase:

What does each alternative cost?

Will each perform the basic functions?

Techniques. Several techniques are available by which alternative ideas can be evaluated and judged. Comparisons can be made between the various advantageous and disadvantageous features of the alternatives under consideration. Advantages and disadvantages of each alternative can be listed and then the ideas sorted according to the relative numbers of advantages and disadvantages. A system of alternately using creative

TABLE 10.2 Questions to Stimulate Ideas

A. Idea stimulators

Eliminate—combine:

Can it be eliminated entirely?

Can part of it be eliminated?

Can two parts be combined into one?

Is there duplication?

Can the number of different lengths, colors, types be reduced?

Standardize—simplify:

Could a standard part be used?

Would a modified standard part work?

Does the standard contribute to cost?

Does anything prevent it from being standardized?

Is it too complex?

Can connections be simplified?

Challenge—identify:

Does it do more than is required?

Does it cost more than it is worth?

Is someone else buying it at lower cost?

What is special about it?

Is it justified?

Can tolerances be relaxed?

Have drawings and specifications been coordinated? Maintain—operate:

Is it accessible?

Are service calls excessive?

Would you like to own it and pay for its maintenance?

Is labor inordinate to the cost of materials?

How often is it actually used?

Does it cause problems?

Have users established procedures to get around it? Requirements—cost:

Are any requirements excessive?

Can less expensive materials be used?

Is it proprietary?

Are factors of safety too high?

Are calculations always rounded off on the high side?

Would a thinner material work?

Could a different finish be used?

B. Analysis techniques

Review all phases of the program being evaluated (speculation phase).

Designate the subordinate problems requiring solution (analysis phase). Determine the data that might help with the evaluation (speculation phase). Determine the most likely sources of data (analysis phase).

Conceive as many ideas as possible that relate to the problem (speculation phase). Select for further study ideas most likely to lead to a solution (analysis phase). Consider all possible ways to test the ideas chosen (speculation phase).

Select the soundest ways of testing the ideas (analysis phase).

Decide on the final idea to be used in the program (analysis phase).

(Continued)

TABLE 10.2 Questions to Stimulate Ideas (Continued)

C. Analysis criteria

Will the idea work?

Can it be modified or combined with another?

What is the savings potential?

What are the chances for implementation?

What might be affected?

Who might be affected?

Will it be relatively difficult or easy to make the change? Will it satisfy all the user’s needs?

and judicial thinking processes for each basic idea to be evaluated can be applied according to the steps shown in the Analysis Techniques portion of Table 10.2.

Procedure. Evaluation may be accomplished either by the generating group or by an independent group. Authorities disagree upon which approach is better. The disagreement grows out of the question of whether people who generate ideas can be objective enough in evaluating them.

1. Establish criteria. The first step is to develop a set of evaluation criteria or standards by which to judge the ideas. In developing these criteria, the team should try to anticipate all effects, repercussions, and consequences that might occur in trying to accomplish a solution. The resultant criteria should, in a sense, be a measure of sensitivity to problems (which might be inherent in changes caused by the new idea). In Table 10.3, three sets of criteria that could be used in the analysis phase are presented under Possible ratings. Factors such as these are really the yardsticks by which the effectiveness of each idea can be tested.

2. Screen ideas. The next step in the procedure is the actual ranking, or rating, of ideas according to the criteria developed. No idea should be summarily discarded; all should be given this preliminary evaluation as objectively as possible. In Table 10.3, a three-part system that can be used to rate ideas is presented under Alternative idea. Ratings and their weights are based on the judgment of persons performing the evaluation. This initial analysis will produce a shorter list of alternatives, each of which has passed the evaluation standards set by the team.

TABLE 10.3 Typical Analysis Rating System

Possible ratings

Excellent

Good

Fair

Poor

Use now

Modify

Hold

Reject

Simple idea

Moderately complex

Complex idea

3. Define alternatives. The remaining alternatives can be ranked according to an estimate of their relative cost reduction potential. The ranking may be based on nothing more than relative estimates comparing the elements, materials, and processes of the alternatives and the original or present method of providing the function. The surviving alternatives are then developed further to obtain more detailed cost estimates. The cost estimating for each alternative proceeds only if the preceding step indicates it still to be a good candidate. Although the analysis phase is the responsibility of the VE team, authorities and specialists should be consulted in estimating the potential of these alternatives. Cost estimates must be as complete, accurate, and consistent as practicable to minimize the possibility of error in assessing the relative economic potential of the alternatives. Specifically, the method used to determine the cost of the original should also be used to cost the alternatives.

4. Make final selection. After the detailed cost estimates are developed for the remaining alternatives, one or more are selected for further study, refinement, testing, and information gathering. Normally, the alternative with the greatest savings potential will be selected. However, if several alternatives are not decisively different at this point, all should be developed further.

![Add smaller shelves to a closet Подпись: The inside of a closet can be arranged to hold much more than clothes on hangers. A bank of shelves can eliminate the need for a chest of drawers. [Photo by Don Charles Blom]](/img/1312/image839.gif)

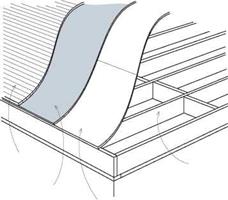

[Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]

[Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.] Cut the shelves to fit between the divider and the closet wall, then nail them to the cleats to further secure the divider.

Cut the shelves to fit between the divider and the closet wall, then nail them to the cleats to further secure the divider.