PARKING

Automobile parking poses a significant land use problem in subdivision planning. In the recent past, common practice provided for wide local streets, often capable of accommodating a row of parked cars on each side in addition to two lanes of moving traffic. Such parking space has often been provided where there are also private driveways and other off-street parking that can accommodate several cars. Good planning can reduce this heavy commitment of land to parking without sacrificing adequate accommodation of vehicles.

Following are guidelines for parking:

• Provide off-street parking areas whenever possible.

• Use common driveways. ‘

• Design paving thickness to meet actual parking load requirements rather than to general standards.

• Eliminate curbs and gutters in parking areas.

• If curbs must be built, use roll curbs or other alternatives to standard requirements.

• If street parking must be used, limit such parking to one side of the street.

• Use unpaved shoulders for parking to reduce road pavement width.

• Consider traditionally unused space, such as in a cul-de-sac or court, for parking.

Reduction of street width reduces both the direct costs of street construction and maintenance, and the indirect cost of unnecessary land use. Elimination of one or both parking lanes along as many streets as possible through off-street parking makes a major contribution to the achievement of these savings.

Reduction of street width reduces both the direct costs of street construction and maintenance, and the indirect cost of unnecessary land use. Elimination of one or both parking lanes along as many streets as possible through off-street parking makes a major contribution to the achievement of these savings.

Off-street parking can be accommodated by various types of common parking areas. Townhouses or clusters lend themselves well to these solutions.

Common off-street parking

Detached units can often share a driveway, eliminating additional curb cuts and their associated costs. The necessary width of a common driveway may vary according to the number of units being served, but should generally be no wider than the usual width of a single driveway.

![]() Two significant variables in the construction cost of parking areas are pavement thickness and requirements for curbs and gutters. Although local requirements for pavement design and curb and gutter construction usually do not apply to private driveways, many do apply to common parking areas. ‘

Two significant variables in the construction cost of parking areas are pavement thickness and requirements for curbs and gutters. Although local requirements for pavement design and curb and gutter construction usually do not apply to private driveways, many do apply to common parking areas. ‘

Pavement thickness should be based on anticipated usage, both with regard to volume and to loadings. Standards that apply to roads and highways are rarely appropriate for residential parking areas.

Typical community standards for residential parking areas specify a minimum base of 4 to 6 inches. However, a 2-inch base of crushed stone is frequently adequate. As is discussed in the section on Streets, the nature and condition of the subsoil must be considered.

Another factor is the question of whether the parking area will be used by heavy vehicles, notably trash trucks. Placement of trash dumpsters and routes for heavier vehicles can be planned to minimize the amount of pavement that such vehicles will traverse, and that must be strengthened to accommodate them.

Curbs and gutters can be eliminated in parking areas; stormwater can be diverted and drained off by sheet flows and swales. Where curb and gutter requirements exist, relatively inexpensive approaches such as roll curbs, extruded asphalt curbs, wheel stops, and integral curbs and sidewalks can be considered in place of more costly approaches. More detailed information is provided in the sections on Curbs and Gutters, and Stormwater Drainage.

Where it is not practical to accommodate part or all of residential parking by off-street facilities, the street must be used. However, the need for street parking must be evaluated on an individual basis. Consideration shpuld be given to confining such parking to one side or to parking on road shoulders, reducing street pavement width.

Where it is not practical to accommodate part or all of residential parking by off-street facilities, the street must be used. However, the need for street parking must be evaluated on an individual basis. Consideration shpuld be given to confining such parking to one side or to parking on road shoulders, reducing street pavement width.

The center of a court or bulb cul-de – sac can accommodate additional parking without increasing street dimensions. A cjuick and relatively simple method is to "stripe” or paint additional parking spaces in the center of the bulb.

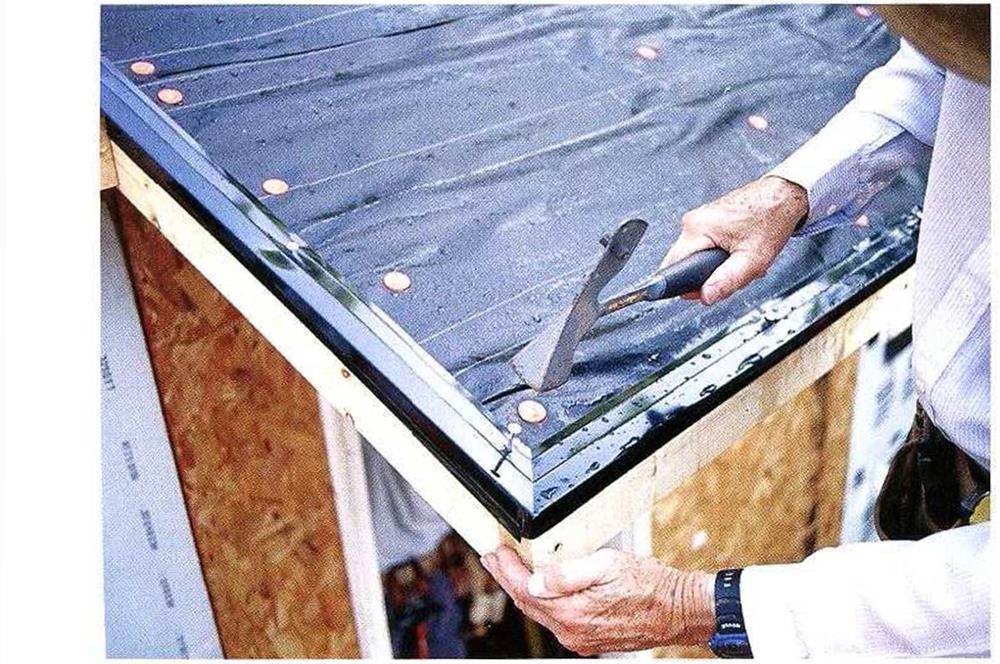

to that line. This makes the roll lay down straight. Alternatively, you can hold the felt Hush with the edge of the roof. Unroll the felt Hat (with no bumps or wr nkles) and tack it down with roofing tacks. A roofing tack is a small nail with a large plastic button (generally green, orange, or red) on top (see the bottom photo on p. 136). Stepping on felt that is not nailed well can cause you to slip off the roof, so use plenty of roofing tacks (6 in. o. c. at the bottom and ends and 10 in. o. c. from top to bottom every 24 in. o. c. across the roof). Roofing tacks hold the felt in place, which is especially important if the roof won’t be shingled for several days. Pick up any tacks that fall to the ground so that no one steps on them. Finally, trim the felt flush with the gable ends.

to that line. This makes the roll lay down straight. Alternatively, you can hold the felt Hush with the edge of the roof. Unroll the felt Hat (with no bumps or wr nkles) and tack it down with roofing tacks. A roofing tack is a small nail with a large plastic button (generally green, orange, or red) on top (see the bottom photo on p. 136). Stepping on felt that is not nailed well can cause you to slip off the roof, so use plenty of roofing tacks (6 in. o. c. at the bottom and ends and 10 in. o. c. from top to bottom every 24 in. o. c. across the roof). Roofing tacks hold the felt in place, which is especially important if the roof won’t be shingled for several days. Pick up any tacks that fall to the ground so that no one steps on them. Finally, trim the felt flush with the gable ends.

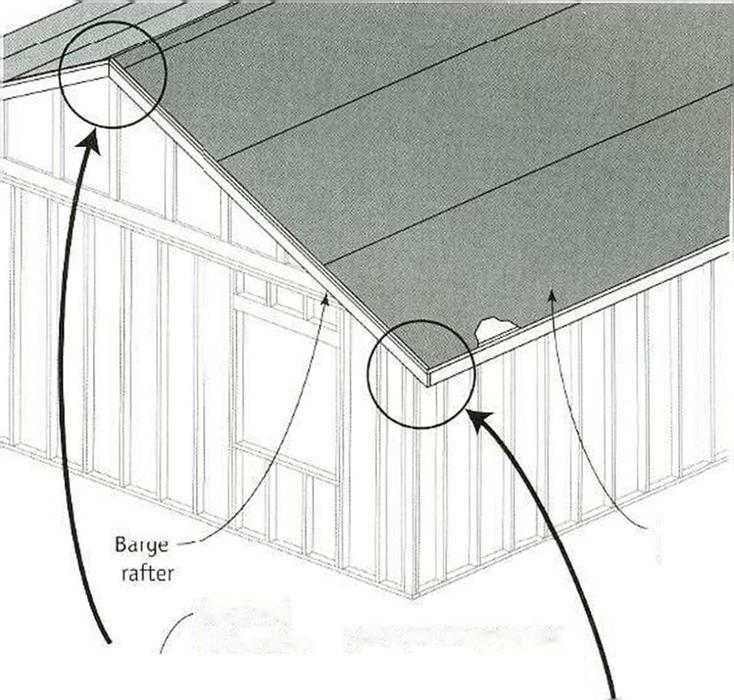

Whether you are tacking down roofing felt or nailing on shingles, it’s important in consider whether the nails can be seer, from below. When the eaves around t he house are open (no soffit), a long nail penetrates the roof sheathing and is visible to anyone who looks up. I kindreds of shiny nails sticking through the plywood or OSB is ur at tractive. Therefore, when tacking felt around the perimeter of the roof, take care to nail the tacks into the barge rafters and gable-end rafters—not just through the sheathing into the air. When nailing shingles, use %-in. nails at the gable overhangs and eaves. When working over the house frame, nails that penetrate the sheathing in the attic are not a problem.

Whether you are tacking down roofing felt or nailing on shingles, it’s important in consider whether the nails can be seer, from below. When the eaves around t he house are open (no soffit), a long nail penetrates the roof sheathing and is visible to anyone who looks up. I kindreds of shiny nails sticking through the plywood or OSB is ur at tractive. Therefore, when tacking felt around the perimeter of the roof, take care to nail the tacks into the barge rafters and gable-end rafters—not just through the sheathing into the air. When nailing shingles, use %-in. nails at the gable overhangs and eaves. When working over the house frame, nails that penetrate the sheathing in the attic are not a problem.