STEP 8 Install and Plumb Door and Window Trimmers

Many builders—even experienced ones— don’t like to spend time plumbing window and door trimmers. But Lve found that this step really makes a better building. If the door

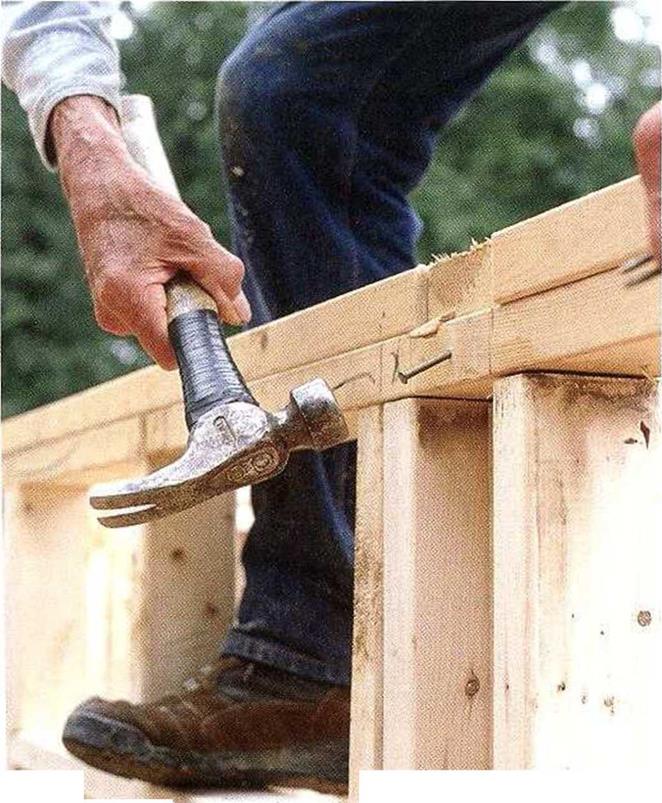

1. Drive this nail first, then bend it over, embedding the shank and head in the adjacent board. [1]

trimmers are plumb, the doors hinge-side

jamb butts solidly against the trimmer along

its entire length. Thercs no need for shims on

this side of the door. That means vou save

/

time and obtain solid, continuous backing for the jamb that supports the full weight of the door. If the opposite trimmer is also plumb, the shims vou install can share the same thick-

г

ness. There’s no fussing to make shims of different sizes. Similarly, window installation benefits from plumb trimmers.

Window trimmers were installed during step 3, when the window assemblies were built on the floor deck. Full-length window trimmers are firmly attached at the bot:om corners

*

of the rough window opening, but each trimmer can still be pried away from its king stud to get the trimmer as plumb and straight as possible. Use a straight claw on a framing hammer or a flat bar to pry and a 2-ft. level to test for plumb and straight. When the trimmer is where vou want it to be, secure it by toenailing through the header with 8d nails. Make sure you toenail from both sides of the wall. To lock a trimmer in straight position, hammer a nail clip into each edge of the trimmer, as shown in the illustration at left.

It’s best not to install door trimmers until after the walls have been raised and braced. This way, each trimmer can be measured and cut to tit snugly up against the bottom of the header. 1 carrv two straight studs to each opening, hold them in position under the header, and mark them to length. When the trimmer has been cut for a snug lit, secure it to the king stud with a single 16d nail driven near the center. Don’t drive any more nails, because you will need to tap the 2x in or pry it out slightly to get it plumb. Test for plumb with a 6-ft. level. When it is plumb, drive toenails through the header and і г to the

trimmer, then toenail the trimmer to the bottom plate.

Finish by getting the trimmer straight, using nail dips, if necessary. When the sheathing is installed, you can lock the trimmers in place by nailing through the sheathing and into the trimmers’ edges.

Hived through the 6.8-magnitude earthquake that hit Northridge, California, in 1992.

Besides nearly scaring me to death, it made me believe in wall sheathing. A 6.8 quake is not even the big one predicted by most seismologists, yet a number of people lost their

ives. More lives would have been lost if critical areas in buildings had not been sheathed with plywood or OSH. Serious damage occurred in those buildings, but they didn’t collapse. The buildings that held up best were small, single-story wood-frame houses, such as those built bv Habitat. iVIanv were knocked

‘ 4

several feet from their foundation, but they didn’t collapse on their occupants.

Unlike dryvvall, stucco, and most exterior siding, plywood and OSH wall sheathing provide both lateral (horizontal) and vertical strength. Sheathing helps hold buildings together and makes a house wind proof, which is important if you live in an area where cold winds are a reality.

|

To straighten a crooked walk you’ll need to move it in or out. To move a wall out, use two Шnails to secure a 2x brace to the nearest

To straighten a crooked walk you’ll need to move it in or out. To move a wall out, use two Шnails to secure a 2x brace to the nearest

PLUMB THE WALLS. While one person holds the level, another person can nudge the wall to get it plumb, then nail off a diagonal brace to keep it that way.

PLUMB THE WALLS. While one person holds the level, another person can nudge the wall to get it plumb, then nail off a diagonal brace to keep it that way.

After the wall is plumb, finish nailing in the metal braces or use temporary 2x stud braces nailed at an angle to hold the wall plumb until it is sheathed. When the exterior walls are plumb, proceed to the interior walls. You can’t straighten a wall until the walls that butt into it have been plumbed.

After the wall is plumb, finish nailing in the metal braces or use temporary 2x stud braces nailed at an angle to hold the wall plumb until it is sheathed. When the exterior walls are plumb, proceed to the interior walls. You can’t straighten a wall until the walls that butt into it have been plumbed.

Nailing the lapped double plate into the adjoining top plates ties the entire framed structure together. This important task, when done accurately, makes it easy to plumb and straighten the walls. II you are a gymnast, like

Nailing the lapped double plate into the adjoining top plates ties the entire framed structure together. This important task, when done accurately, makes it easy to plumb and straighten the walls. II you are a gymnast, like

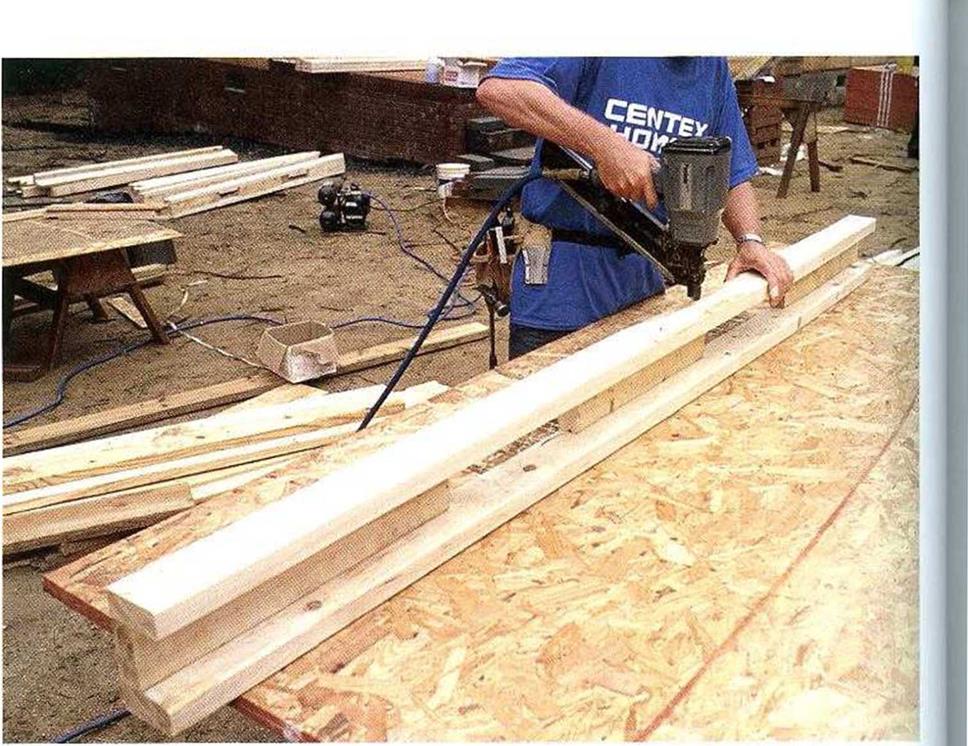

Use a sledgehammer to move the wall until itisright on the chalkline and flush at the ends with the correct marks on the subfloor. After the wall is in position, nail through the bottom plate and into the subfloor, using one

Use a sledgehammer to move the wall until itisright on the chalkline and flush at the ends with the correct marks on the subfloor. After the wall is in position, nail through the bottom plate and into the subfloor, using one embedded in framing lumber. Don l nail in donrwavs, Ьіч-aiise you’ll be cutting out the plate later when you set the door frame.

embedded in framing lumber. Don l nail in donrwavs, Ьіч-aiise you’ll be cutting out the plate later when you set the door frame.

At channel marks, leave 3k-in. cutout so that an intersecting wall can comfortably lap over and tie in at that spot (see the photo on p. 98). When cutting and installing double top plates, leave about a 3k in. gap where the walls tie into each other. This makes it easier for the overlapping double top plates to

At channel marks, leave 3k-in. cutout so that an intersecting wall can comfortably lap over and tie in at that spot (see the photo on p. 98). When cutting and installing double top plates, leave about a 3k in. gap where the walls tie into each other. This makes it easier for the overlapping double top plates to

slip into place. This is another one of those times when it’s okav to be less than absolutely

slip into place. This is another one of those times when it’s okav to be less than absolutely