Happiness Is My Own Bedroom

CONTRARY TO WHAT PEOPLE MAY

think, having a lot of brothers is not always fun. I know. I am the only girl in a family with six children. When there are so many kids, vou need a big house, but our family could not afford one.

We used to live in a very small house with just two and a half bedrooms. This may sound funny, but there were only two bedrooms, plus a space next to the washer and dryer where my oldest brother slept. My parents and baby brother slept in one of the bedrooms, and the other bedroom was for my other three brothers and me. My oldest brother didn’t have much room next to the washer and

dryer, but at least he didn’t have to share a room with three brothers.

Sharing a room with so many

O t

brothers was not much fun for me or for them. But one day when 1 came home from school, I heard some very exciting news. My parents sat us all down in the living room and told us that we were being given the opportunity to get a bigger house by an organization called Habitat for I lumanity. I just kept thinking about the bedroom that they told me I’d have all to myself. I could hardly sleep that night.

We now live in our Habitat home. Habitat really helped my family and changed my life forever.

-Ashley Hanners

frames square. This makes for quality construction and an easier time nailing the top and bottom plates.

Distribute studs, corners, and channels

Ask your crew to distribute studs along one ol the exterior through walls, with one stud per layout mark. Place the studs against the two tacked-down plates. Where corners and channels are required, decide which corner style you want to use. The sidebar on the facing page explains the main types of corners and channels. You can build corners and channels in place as you frame the walls, or you can build them all at once in a central location.

then distribute them and insert them in the walls as needed.

Keep your eyes open for studs that are bowed, twisted, or crowned. Set them aside to use for blocking and roof braces. This ensures a more uniform finished wall and makes it easier for finish carpenters to install cabinets, countertops, and interior trim. Its always good to think about how to make future tasks easier.

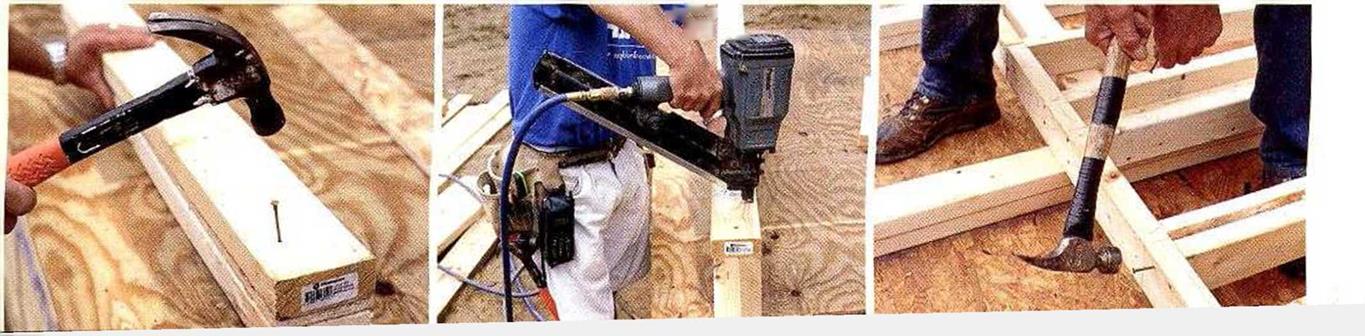

Nail on the top and bottom plates

It’s finally time to pry apart the two wall plates, that you tacked together in step 2. Working on one wall at a time, separate the top wall plate

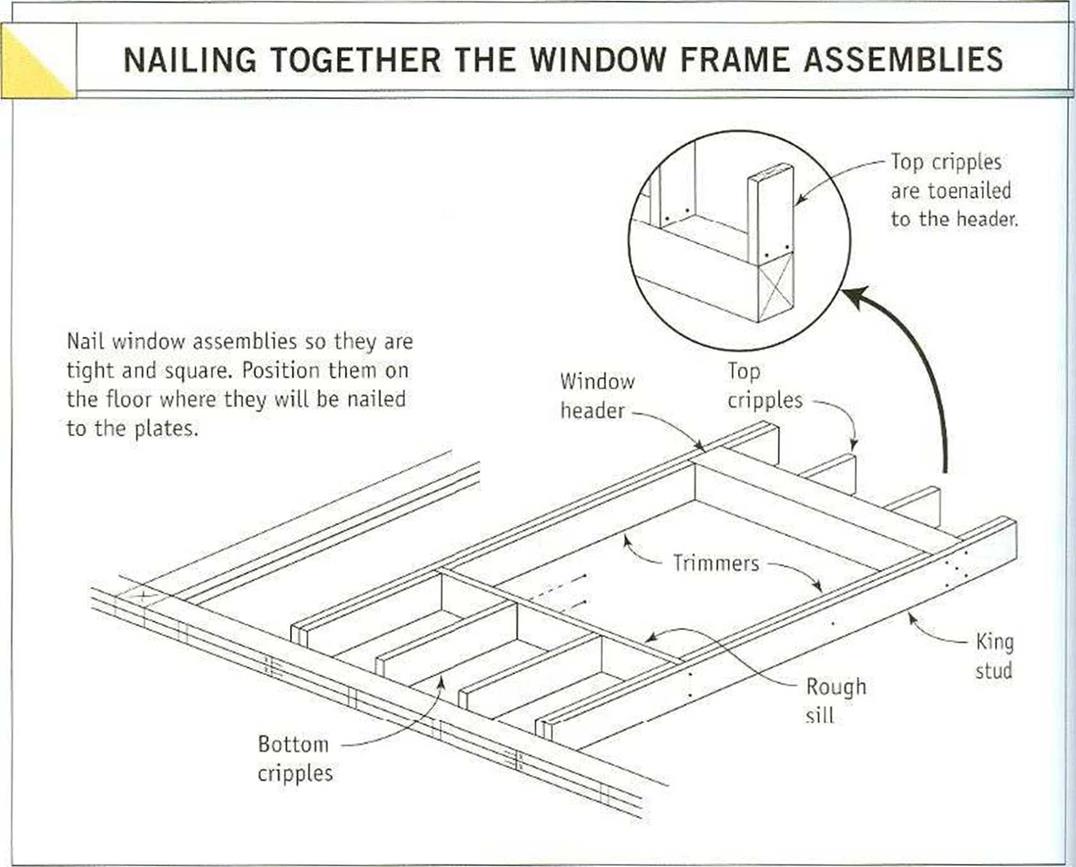

the lengths written on each header, livery header takes a cripple im each end and one on each layout mark. Pay close attention! Place bottom cripples perpendicular to the wall plates, exactly where they will be nailed in place. 1 also place a trimmer and a king stud next to each window opening before I do any nailing.

the lengths written on each header, livery header takes a cripple im each end and one on each layout mark. Pay close attention! Place bottom cripples perpendicular to the wall plates, exactly where they will be nailed in place. 1 also place a trimmer and a king stud next to each window opening before I do any nailing.![STEP5 Build the Walls Подпись: A FULL DECK OF DOOR AND WINDOW ASSEMBLIES. These assemblies are nailed together and ready to be installed between the top and bottom wall plates. [Photo Larry Наші.]](/img/1312/image348_0.gif) With all the walls plated and the window and door frames nailed together, you’re ready to frame the walls. At tins stage, its smart to check vour work. Make sure that the framing members are flush with each other and nailed tightly together. Keep the door and window

With all the walls plated and the window and door frames nailed together, you’re ready to frame the walls. At tins stage, its smart to check vour work. Make sure that the framing members are flush with each other and nailed tightly together. Keep the door and window

corners and channels so you’ll have space on which to nail door and window trim. In hurricane and earthquake /ones, exterior walls must not have window or door openings less than 4 ft. from an exterior corner.

corners and channels so you’ll have space on which to nail door and window trim. In hurricane and earthquake /ones, exterior walls must not have window or door openings less than 4 ft. from an exterior corner.

![Techniques CARRYING LUMBER Подпись: 6]/4 in. (top cripple length) Make a story pole from a 2x s:ud. This pole will help you accurately lay out trimmers, headers, rough sills, and top and bottom cripples.](/img/1312/image313.gif)

Select straight plates. Check 2x plate lumber for bow and twist and select only the straightest boards for plates. This makes for strong, straight walls.

Select straight plates. Check 2x plate lumber for bow and twist and select only the straightest boards for plates. This makes for strong, straight walls.