The “belle epoque” of the Middle Ages, from the dawn of the 12th century to the Hundred Years’ War

The hydraulican-monks: Benedictines and Cistercians

We have seen that the earliest Benedictine monasteries at the end of the 8th century already were employing a range of hydraulic techniques to support their activity. Much later, in the 12th century, Saint Bernard founds the abbey of Citeaux in Bourgogne, and with it the order of the Cistercians. Throughout Europe (France, Germany, Holland, Portugal) the Cistercian abbeys are established near watercourses. But after several years of growth, these abbeys typically found it necessary to augment their water supplies through capturing other rivers or torrents.

The Obazine (Aubazine) abbey was founded in Limousin in 1130 by the hermit Etienne. This abbey quickly entered the fold of the Cistercian order. Here one can identify the trace of the “canal of the monks” dating from around 1150. It is 1.6 km long aqueduct built in truly acrobatic fashion, sometimes laid along a cliff on cantilevered arches, sometimes crossing rocky outcrops. This little canal is only 1.2 m deep and 0.6 m wide; its slope is relatively flat along most of its length (5 m/km), but it ends in a virtual waterfall, descending some 60 m in its last stretch of 230 m. Several centuries later, the ingenuity reflected in this canal is attributed to miracles performed by its founder:

“It should be further noted that the great Saint Etienne had an aqueduct built to bring water into the abbey, so that all normal needs of hygiene and cleanliness could be satisfied. There has never been seen in France a better built or more expensive canal. It passes through inaccessible places where the Saint broke through the rocks, to the admiration of all those who see it, and, according to legend, we learn that one of these rocks, not having yielded after long and expensive efforts, finally crumbled of its own accord after prayers and the worthiness of the Saint to receive this flow of water.’,z, u

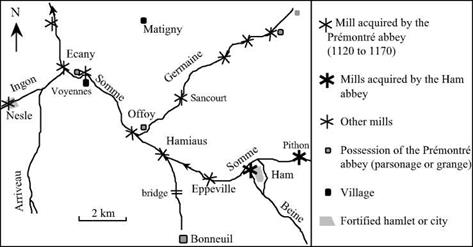

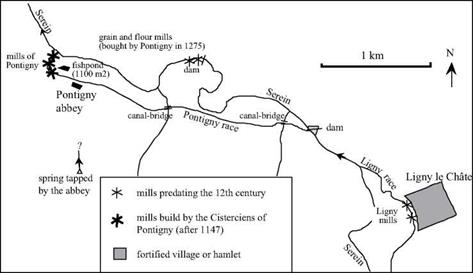

Citeaux is the initial site of the Cistercians, and at the end of the 12th century it was a very rich abbey. But the Vouge River on which it was situated did not have a sufficiently ample and regular flow to support the growing population of monks. The abbots covet the water of a gushing torrent called Cent-Fonts, some ten kilometers to the north of the abbey, which powers numerous mills belonging to several local lords. The abbots begin by obtaining a piece of land from one of these lords to build their own mill, between 1175 and 1180. Little by little, in exchange for salvation of the lords’ souls, they obtain significant land holdings for their scheme as well as shares in the mills that use the water of this torrent. Adding to their holdings through outright purchases, the abbots eventually own all of the mills. From the Duke of Bourgogne and the Bishop of Langres, the most important personages of the region, they obtain all the authorizations necessary for their project of capturing the Cent-Fonts, in return for which they agree to build and maintain bridges across the canal for the use of the peasants of Noiron, a village on the projected course of the canal (Figure 9.10).

|

Figure 9.10 Water and land development at the Cistercian abbey of Citeaux in Bourgogne: derivation canal, mills, pond drainage, between 1175 and 1227 (Berthier, 1996; Sonnet, 1998). |

The canal itself is finally built around 1212. Some ten kilometers long and 2 m wide, it crosses the Varaude River, a tributary of the Cent-Fonts, on a 12-meter long canal-bridge (Figure 9.11). Its slope varies from 1.9 to 5.9 m/km, and it probably captures all of the water of the Cent-Fonts (around 320 l/s). Indeed, the mills located between the canal intake and the confluence of the Varaude are left without any water and thus are abandoned. The monks develop the land that they have acquired, draining the fields crossed by the canal by digging ditches and creating ponds.[479]

|

Figure 9.11 The bridge of Arvaux, carryng the Cent-Fonts canal to the north of Noiron (reconstructed to the original in 1747) (photo by the author). |

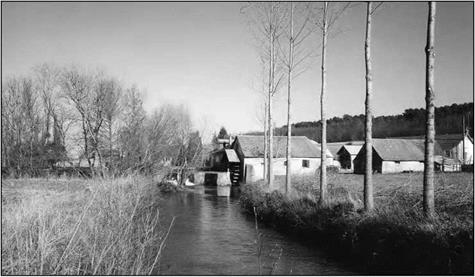

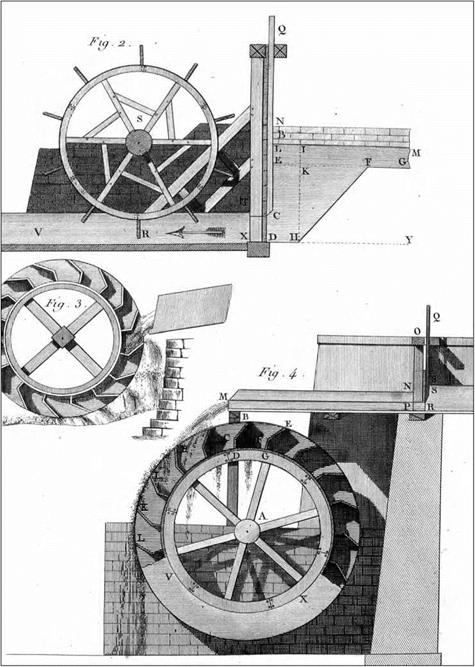

What did the monasteries do with all this water? In general terms the water was destined for two uses: pure water for human consumption, and abundant and fast-flowing water for hygiene and useful work. Captured source water is decanted in reservoirs, sometimes filtered, and then delivered to kitchens, bathrooms, laundries, and to the apartments of the abbot and his guests. In the monasteries of the order of Chartreux, whose rules require total isolation, each cell has its own supply of water and means of wastewater disposal. The supply pipes are made of clay or lead and even sometimes of wood. Water from a river powers the mills of the abbey, including at least one wheat mill and one fuller’s mill, and often several other multiple-purpose mills. Water circulates through the drains and keeps them clean, passes through latrines (the latrine of Royaumont being the most remarkable), and supplies the fish pond. Fish raising is very important, for the monks are forbidden to eat meat by the rules of Saint Benoit. This importance is emphasized by the large size of the fish pond of Obazine, which is 33 m long, 14.5 m wide, and 3 m deep.

|

Figure 9.12 The Cent-Fonts canal, on the Arvaux bridge (left), and where it arrives at the mill of the Cteaux abbey (right) (photos by the author). |

Figure 9.9 Remains of a tower mill on a hilltop in the northern extremity of Corsica. In this particular case, the unit cannot be turned into the wind (photo by the author).

Figure 9.9 Remains of a tower mill on a hilltop in the northern extremity of Corsica. In this particular case, the unit cannot be turned into the wind (photo by the author).

Figure 8.16 The city of Huzhou, near the south bank of Taihu lake. This city is linked to Hangzhou and to the Grand Canal by a network of canals. “It is one of the largest and most considerable cities of China, due to its richness, its commerce, the fertility of its land, and by the beauty of its waters and mountains.” (du Halde, 1735 – ancient archives ENPC).

Figure 8.16 The city of Huzhou, near the south bank of Taihu lake. This city is linked to Hangzhou and to the Grand Canal by a network of canals. “It is one of the largest and most considerable cities of China, due to its richness, its commerce, the fertility of its land, and by the beauty of its waters and mountains.” (du Halde, 1735 – ancient archives ENPC).