Renting a Paint Sprayer

Don’t rent spraying equipment that isn’t well maintained. A first-rate rental company will size the pump to your job, recommend spray tips, and explain how everything works. For good measure, ask for an operator’s manual, too.

Finally, get satisfactory answers to these questions: (1) Is the equipment clean? Rental companies charge extra if equipment is returned uncleaned. (2) Was the last paint used in the sprayer oil-based paint or latex? (3) Can you show me how to use this model?

The last question is especially helpful if you’re a bit macho and don’t want to admit that you’ve never operated any sprayer before. Another face-saver is, "Say, run a little water and show me how to pressurize this, would you?" Don’t leave the rental yard without understanding how the equipment works.

![]()

A quality paint job takes preparation, patience, and experience. In addition, professionals also learn how to streamline their moves. As one pro put it, "Any time you eliminate a move in painting, you save time.”

Almost all paints, including latex, contain volatile organic compounds (VOCs), which are hazardous. So although latex is relatively benign, the following advice is pertinent for all kinds of paints and stains.

Read the label. There’s valuable information on all paint containers: drying time, coverage, thinner data (what to use and how much), and safety instructions. Should an emergency arise—say, a child swallows some paint—the guidance you need may later be concealed under paint drippings. So read up before you open the can or, better, remove and save the label.

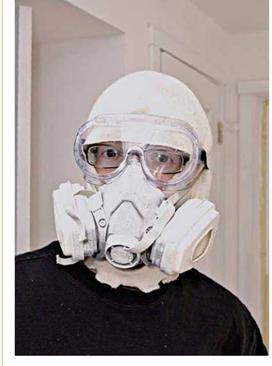

Don’t breathe paint fumes. Breathing paint or solvent fumes can make you dizzy; impair your judgment; and, over a sustained period, damage your brain, lungs, and kidneys. Set up a fan to blow fumes away from your work area, and always wear a half-face mask with replaceable cartridges. Rule of thumb: If you can smell fumes while wearing a snug mask, change the cartridge.

Ventilation is a particular problem when chemically stripping paints because the chemicals are strong and because heat guns, sanders, and scrapers increase airborne particles. The now banned lead-based paints are especially dangerous when inhaled or ingested, so if you suspect that you will be stripping lead paint, always test it before disturbing it. See "Lead-Paint Safety,” on p. 442, for more.

Avoid getting paint in eyes and on skin.

Although most water-based paints are innocuous,

Skin CARE

To minimize chemical contact with your skin, (1) wear goggles, especially when using chemical strippers; (2) use an extension pole so you don’t need to stand immediately beneath a roller; (3) don’t overload brushes and rollers; (4) brush or roll away from your face, especially on the first few strokes after loading up with paint.

oil-based paints can be extremely irritating. In most cases, flush your eyes with water if you get paint in them, and visit a doctor immediately.

There are few things you can do to protect your skin. Before you start, apply lotion to your skin to reduce irritation and speed cleanup. Also, wear gloves, even when using latex, because any paint will irritate skin over time. Gloves are a must for oil-based paints.

When it comes to cleanup, painters have traditionally used paint thinner or turpentine to clean their hands and then washed with hot soapy water. However, hot water opens skin pores, causing them to absorb more solvent than otherwise. Instead of volatile solvents and hot water, it may be safer to use waterless hand cleaner and wipe it off with paper towels.

Store paint safely. Store paint where children can’t reach it. Solvents such as paint thinner, turpentine, and all paints—including latex—should be considered toxic and stored out of reach of children. (In fact, some "green” brands of latex such as Glidden’s 2000™ and AMF Safecoat® contain no VOCs, but you still wouldn’t want kids to drink them. So store these products safely, too.) Also, store paint where temperatures are moderate, because freezing ruins their bonding ability and heat increases their volatility. Close all containers completely so the paint doesn’t dry out and contaminants can’t get in. Never store rags or steel wool dirty with solvents, because of the danger of spontaneous combustion. Dispose of such articles safely: Most paint-can labels carry disposal suggestions, and many municipalities have annual curbside pickups of such materials.

paint bucket about half full. This ramp gives you room to load the roller and remove excess paint quickly—so you can keep painting, rather than repeatedly filling a roller pan.

paint bucket about half full. This ramp gives you room to load the roller and remove excess paint quickly—so you can keep painting, rather than repeatedly filling a roller pan.

Speaking of mixing, have your paint store mechanically shake the paint for you—unless, of course, the manufacturer’s instructions indicate it shouldn’t be shaken. For example, polyurethanes and varnishes trap air bubbles when shaken.

Speaking of mixing, have your paint store mechanically shake the paint for you—unless, of course, the manufacturer’s instructions indicate it shouldn’t be shaken. For example, polyurethanes and varnishes trap air bubbles when shaken.

Because the underside is the most visible part of the box beam from eye level, measure to be sure the board reveals are consistent. Measuring also tells you exactly where the edge of the bottom board is—so nails don’t miss it. Cover gaps along the ceiling with crown molding.

Because the underside is the most visible part of the box beam from eye level, measure to be sure the board reveals are consistent. Measuring also tells you exactly where the edge of the bottom board is—so nails don’t miss it. Cover gaps along the ceiling with crown molding.

To determine that angle, cut a short section of crown molding to use as a seating gauge.

To determine that angle, cut a short section of crown molding to use as a seating gauge.

When installing nailing blocks without backing trim, nail the blocks directly to the wall plates. Keep a 1/16-in. space between the back of the molding and the face of the blocks to accommodate wall-ceiling irregularities.

When installing nailing blocks without backing trim, nail the blocks directly to the wall plates. Keep a 1/16-in. space between the back of the molding and the face of the blocks to accommodate wall-ceiling irregularities.

But in the old days, windowsills were pitched all the way, front to back, which created a uselessly pitched interior section that had to be covered with a stool piece, as shown in "Window Trim," on p. 421. To fit a pitched sill, usually set at 14° to 20°, the underside of a stool must be partially rabbeted at the same angle, so that when the stool is nailed on top of the sill, the top face of the stool will be level. It’s an archaic design but, surprisingly, it survives in some new window designs.

But in the old days, windowsills were pitched all the way, front to back, which created a uselessly pitched interior section that had to be covered with a stool piece, as shown in "Window Trim," on p. 421. To fit a pitched sill, usually set at 14° to 20°, the underside of a stool must be partially rabbeted at the same angle, so that when the stool is nailed on top of the sill, the top face of the stool will be level. It’s an archaic design but, surprisingly, it survives in some new window designs.

2. Although many carpenters install both jamb casings before measuring the head casing, this carpenter chose to dry-fit the second jamb and head as a pair, so he could adjust the miter joint in place. An unglued biscuit held the pieces of casing together as he finessed the joint.

2. Although many carpenters install both jamb casings before measuring the head casing, this carpenter chose to dry-fit the second jamb and head as a pair, so he could adjust the miter joint in place. An unglued biscuit held the pieces of casing together as he finessed the joint.